Fine thread versus coarse thread screws

Learn key differences between fine thread and coarse thread screws to distinguish your preferred option

Quick guide – fine thread versus coarse thread design

Q. What is the difference between fine and coarse thread fasteners?

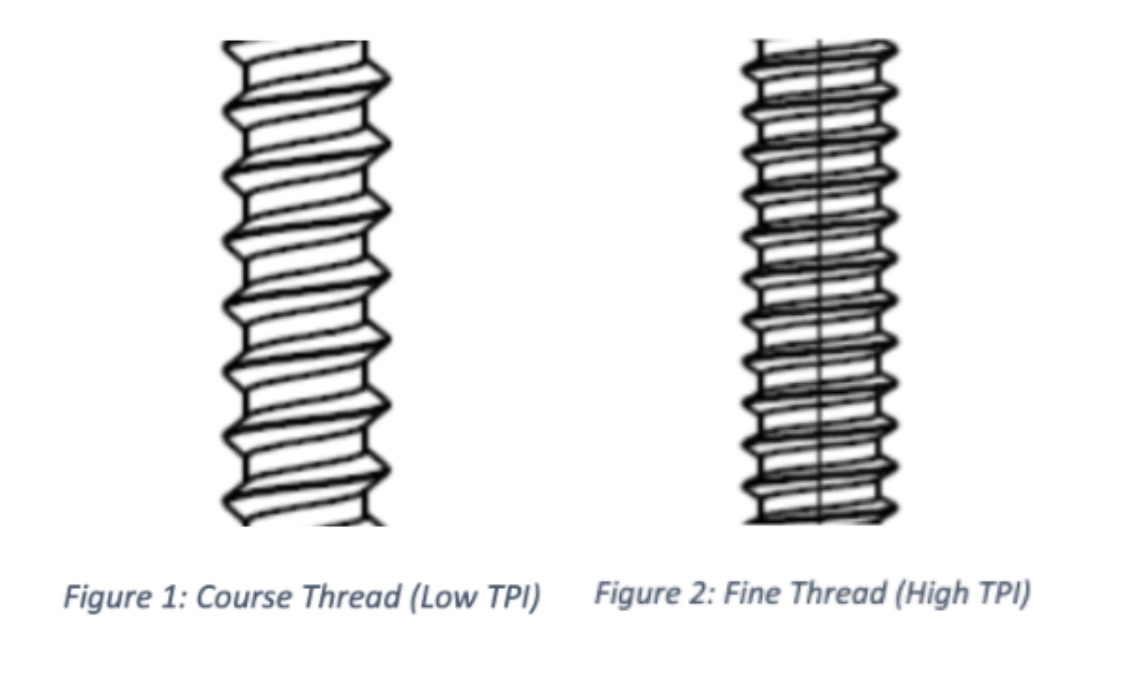

A. A fastener with a fine thread equates to a fastener with a large number of threads per distance along the fastener. In contrast, a coarse thread fastener equates to a fastener with a low number of threads per distance along the fastener.

Q. Is fine thread stronger than coarse thread?

A. For fasteners with the same nominal size, fine thread fasteners are stronger than coarse.

Q. Do fine or coarse threads provide better corrosion resistance?

A. Corrosion resistance is related to fastener material and the plating or coating used on the product. There is no corrosion advantage for coarse or fine thread fasteners. Read our guide about protecting your buildings from corrosion to learn more.

Q. When should I use fine thread fasteners vs coarse thread fasteners?

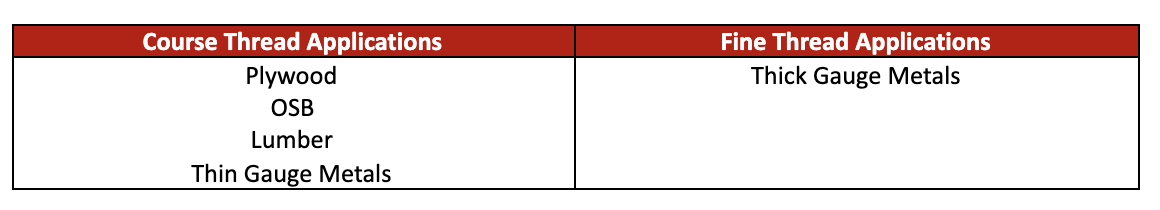

A. This will depend on the specific application. However, as a general rule of thumb, coarse thread fasteners should be used in brittle applications (ply-wood, OSB, SPF, etc..) or thin gauge metal applications.

The difference between fine and coarse thread

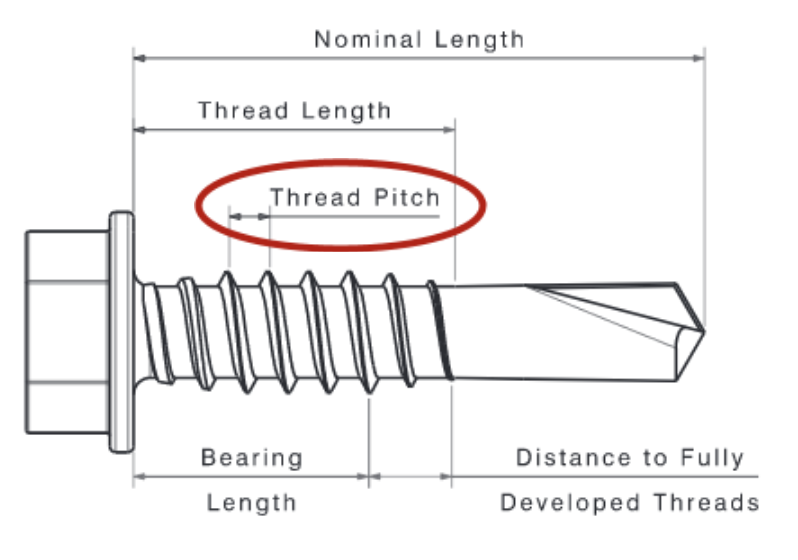

When discussing fine and coarse threads, construction teams are actually discussing the underlying value of thread pitch. This can be defined as the distance between two threads on the shaft of the fastener. This is typically measured in threads per inch (TPI). A higher value TPI indicates a smaller thread pitch.

A fastener with a fine thread equates to a fastener with a high TPI value. In contrast, a coarse thread fastener equates to a fastener with a low TPI value.

Which is stronger: fine or coarse threads?

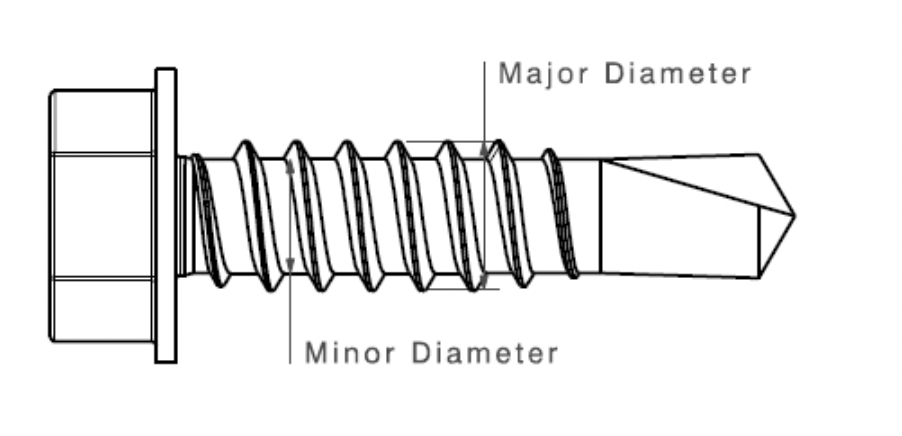

Strength characteristics such as tensile and shear performance are only tangentially related to thread pitch. The minor diameter of the fastener is actually the value that influences strength characteristics. This can be defined as the unthreaded diameter of the shaft. In contrast, the major diameter is the threaded diameter of the shaft, which determines the nominal size of the fastener.

Fastener sizes are nominally described by their major diameter value. In the United States, this is typically labeled by a pound sign followed by a number (example: #12). Due to manufacturing constraints, fine thread fasteners will always have larger minor diameter values than their coarse thread counterparts of the same size. This means that, for two fasteners of the same size and material, the fine thread fastener will have better strength characteristics.

Which provides better corrosion resistance: fine or coarse threads?

The thread profile of a fastener has no bearing on its corrosive resistance in real-world applications. This is typically determined by the plating or coating applied to the fastener. For an in-depth guide, see our white paper on corrosion resistance.

Contact SFS by Calling (610) 376 5751 to discuss whether fine or coarse thread fasteners would better accommodate your project's particular needs. Our team can answer all questions, recommend specific parts, and discuss the various ways we can help you achieve your goals.

When to use fine thread fasteners vs coarse thread fasteners

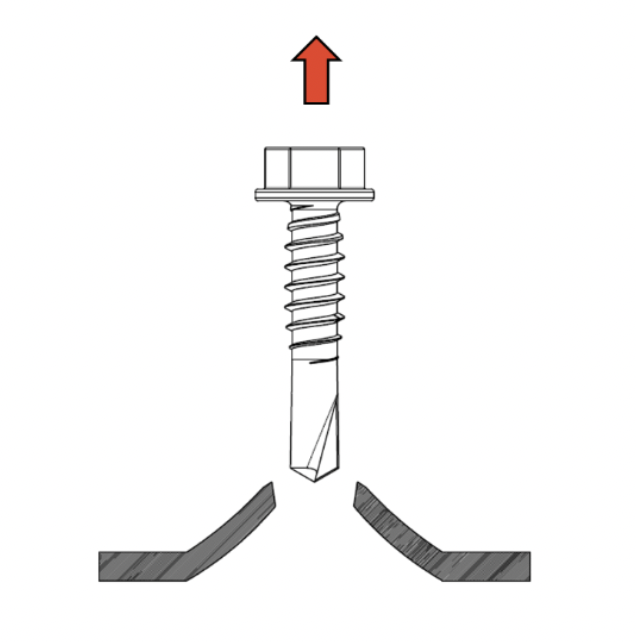

The installation material is the most important factor when selecting a fastener thread profile. This is due to the resultant pull out resistance that is determined by the thread profile. Pull out can be defined as the maximum tensile load at which a fastener’s threaded connection remains intact in the application substrate.For most secondary attachment applications (roofing, cladding, rainscreen, commercial construction, etc.) the following rules are applicable:

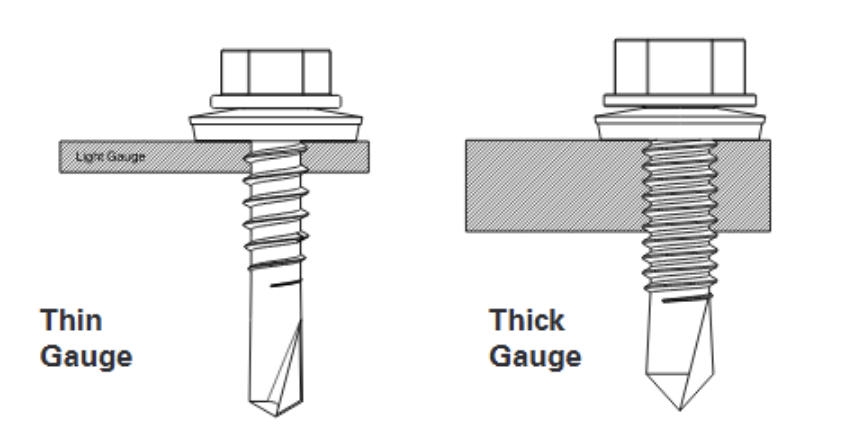

1. Fine thread fasteners should be used in conjunction with thick gauge metal applications. Coarse thread fasteners should be used in conjunction with thin gauge metal applications.

Coarse threads have a "clamping" function when used in thin gauge applications which increases pull out resistance. This type of "clamping" action, where the substrate is locked between threads would not be possible with fine threads. However, fine threads provide more connection points in thick gauge material, which aids in pull out performance. In addition, due to the small difference between the minor and major diameters of fine threads, it typically requires less effort to drive these types of fasteners into robust substrates.

2. Fine thread fasteners should be used in conjunction with thicker and more robust metal applications. Coarse thread fasteners should be used in conjunction with more brittle materials, such as plywood, OSB, and 2" x 4" lumber.

Fibrous materials, such as plywood, tend to embed more readily in coarse thread profiles. This provides additional pull out resistance, as a larger surface area of the threads are in contact with the substrate. Although this attribute would be beneficial in thicker metal applications, difficulty during the installation process makes it nearly impossible to fully seat fasteners with coarse threads.

SFS can help you determine your ideal fastener

Call 610-376-5751 for guidance selecting the best-suited coarse or fine thread screw for your upcoming project. Alternatively, we welcome you to explore popular products such as our cladding fasteners or self tapping screws.

English (Canada)

English (Canada)

čeština (Česká republika)

čeština (Česká republika)

magyar (Magyarország)

magyar (Magyarország)

Deutsch (Deutschland)

Deutsch (Deutschland)

eesti (Eesti)

eesti (Eesti)

español (España)

español (España)

português (Portugal)

português (Portugal)

suomi (Suomi)

suomi (Suomi)

français (France)

français (France)

English (United Kingdom)

English (United Kingdom)

italiano (Italia)

italiano (Italia)

Nederlands (Nederland)

Nederlands (Nederland)

norsk, bokmål (Norge)

norsk, bokmål (Norge)

polski (Polska)

polski (Polska)

svenska (Sverige)

svenska (Sverige)

Türkçe (Türkiye)

Türkçe (Türkiye)