Rainscreen cladding materials: what are the different benefits?

Rainscreens are exterior walls installed to strategically shield buildings from damage-causing moisture and other environmental factors. Rainscreen cladding materials span a diverse range of textiles, from metal to porcelain, each bringing unique strengths. Below are many of the materials utilized with rainscreens. However, this is not a comprehensive list

Metal Rainscreen Types

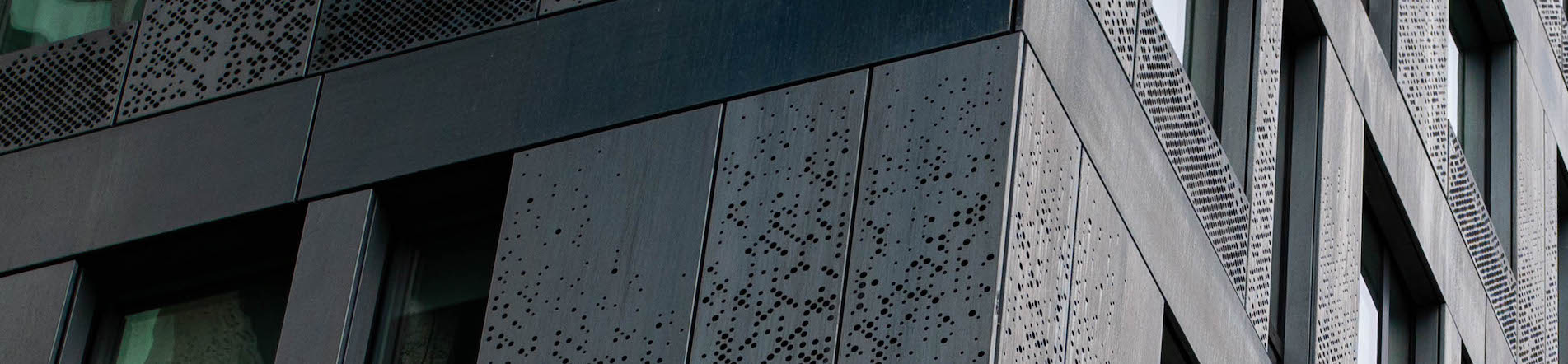

There are numerous metals available for rainscreen facade panels. Each offers a different durability, appearance, weight, and reaction to the elements. SFS, a maker of rainscreen facade support systems, works with metal rainscreen panels often. Read about the project pictured here: MAACM Metal Rainscreen or read about SFS's involvement with raw copper and zinc rainscreen cladding in NYC. Read about the different metal materials options below:

Metal composite materials (MCM) combines two different metals

Architects don’t necessarily need to only choose one metal for their cladding. To leverage the benefits of multiple textiles, architects sometimes utilize metal composite materials (MCM), such as ACM (aluminum composite metals). These panels consist of two outer metal layers which bond to surround a plastic center—such as polyurethane or polyethylene—designed to provide fire resistanceSteel cladding

There are numerous kinds of steel that can be used in rainscreen cladding, each presenting its own benefits.

Stainless steel - In addition to providing an attractive finish, stainless steel rainscreen panels have a chromium oxide exterior that prevents the buildup of rust.

Galvanized steel - Unlike the above, this alternative comes with a coat of zinc to protect rainscreen panels from the elements. The main difference from stainless steel is the exterior pattern, as the galvanized version created a dynamic “spangled” aesthetic.

Weathering steel - This provides protection from the damage of corrosion. However, it purposely takes on the rugged tones associated with rust.

Zinc cladding

Zinc is arguably one of the more durable metals mentioned in this article. In addition to its resistance to moisture, it is near-immune to UV rays. Plus, small dents will disappear with time. These advantages make it particularly practical for rainscreen cladding.

Aluminum cladding

Aluminum offers the same protection from rust as steel but with less weight. However, its lighter structure makes it more vulnerable to scrapes.

Titanium cladding

Titanium is attractive, light, strong, and builds a protective layer against the elements. Be aware that titanium will require regular cleaning or else it risks stains.

Copper and brass cladding

Both copper and brass are chosen primarily for their distinct coloration. Brass may be favored for its malleability and golden hue, making it highly decorative. Alternatively, copper is the stronger of the two and is easily recycled.

Ceramic and stone cladding

Stonework adds an inviting aesthetic that also requires minimal cleaning and is generally resistant to pollution. Dependent upon the glazing process, the UV resistance of natural products is particularly noteworthy. Additionally, stonework cladding offers better fire resistance than other types of claddings.

Read about specific stone materials used as cladding below:

Terracotta cladding

A Terracotta panel is created by hand molding, pressing, or extruding wet clay into the shape of a panel. The panel is then fired to harden the shape. If desired, this is followed by glazing before being fired again. This process allows flexibility in the following ways:

Panels can come in a multitude of dimensions and patterns, creating unique textures impossible to replicate with metal

Color choices are not limited and remain vibrant over time

Attachment of the panel to the building structure is typically hidden behind the panel instead of displaying the fasteners

Unlike some other types of ceramic and stone cladding, terracotta panels are usually mechanically anchored to the building.

Porcelain cladding

A porcelain panel is created by mixing clay and other minerals together with water. After removing excess moisture from the mixture, it is pressed into a mold that solidifies the mixture. Similar to Terracotta, the panel can be coated with glazing and fired. This process provides the following benefits:

Porcelain is stronger and thinner than molded/extruded clay

Relatedly, it is less porous than ceramic, fiber cement, and terracotta

Because color is coated on, porcelain can take on a diverse assortment of colors and textures

Attachment of the panel to the building structure is typically hidden behind the panel instead of displaying the fasteners

Unlike ceramic, the thinness of porcelain cladding allows it to adhere to the exterior. However, this can prevent its usage for taller structures.

Ceramic cladding

A ceramic panel is created similarly to porcelain, but the minerals and binders used are pressed into the molds with less force and the firing takes place at a lower temperature. As a result:

Can be cheaper than porcelain panels

Cutting can be easier due to the less dense nature of the product

Fiber cement cladding

A Fiber Cement panel is made from a mixture of pulp, cement, and cellulose fibers. The slurry is poured between metal rollers to remove moisture and create a thin film. It is then transported along a belt which vacuums out more water to create a thinner sheet. These are layered on top of one another to form the desired thickness of the panel before being passed between rollers to remove more moisture. As the final steps, surface textures are applied and the fiber cement panels are baked in a pressurized oven. Benefits of this process include:

Larger sheet sizes

An affordable alternative to natural products like terracotta and porcelain

Enables face fastening, an affordable alternative to concealed fastening

Lacks the brittleness of ultra-high performance concrete (UHPC) or other natural products

Fiber cement cladding also comes in the following forms:

GFRC is similar to the fiber cement described above except that it uses glass fibers in place of cellulose.

An Ultra High-Pressure Concrete (UHPC) is similar to a fiber cement panel except that it uses metal fibers to reinforce the mixture. Instead, the slurry, molding, and curing processes are highly regulated to create a high compression strength panel. Benefits include:

UHPC absorbs less water than GFRC and other fiber cement cladding types

The molding enables varying shapes

Timber Cladding

Timber cladding, also referred to as timber weatherboarding, is affordable and highly attractive. Designers can choose from an array of woods like oak and cedar, as well as arrange the cladding in artistic patterns for a distinct appearance.

There are eco-friendly upsides as well. The timber can be sourced from FSC and PEFC-certified suppliers which guarantee 100% renewability. Plus, the wood collects carbon from the atmosphere to help fight the causes of global warming.

Glass cladding

Though rarer than other types of cladding materials, glass rainscreen materials attract some architects due to its decorative properties. Further enhancing its polished aesthetic, it’s immune to permanent staining or graffiti, making it a low-maintenance choice. Additionally, it is resistant to moisture.

HPL cladding

High-Pressure Laminate Panels (HPL) façades consist of kraft paper reinforced with resin. Manufacturers design higher grades to withstand weather, chemicals, and fire. Generally speaking, HPL offers architects with a more affordable alternative to other rainscreen cladding materials. What’s more, there are near-endless options for colors and aesthetic prints.

SFS can help you find the ideal rainscreen system

SFS supports Nvelope rainscreen cladding systems to accommodate a variety of textiles and design needs. Have questions? Reach out to our SFS experts to find out about more about installing the ideal rainscreen for your building and the services we offer.

Contact SFS by calling (610) 376 5751.

English (Canada)

English (Canada)

čeština (Česká republika)

čeština (Česká republika)

magyar (Magyarország)

magyar (Magyarország)

Deutsch (Deutschland)

Deutsch (Deutschland)

eesti (Eesti)

eesti (Eesti)

español (España)

español (España)

português (Portugal)

português (Portugal)

suomi (Suomi)

suomi (Suomi)

français (France)

français (France)

English (United Kingdom)

English (United Kingdom)

italiano (Italia)

italiano (Italia)

Nederlands (Nederland)

Nederlands (Nederland)

norsk, bokmål (Norge)

norsk, bokmål (Norge)

polski (Polska)

polski (Polska)

svenska (Sverige)

svenska (Sverige)

Türkçe (Türkiye)

Türkçe (Türkiye)