Types of wood beam connectors: What you need to know

Wood beams are commonly leveraged in building construction, often as critical load-bearing elements. They consist of different materials, including solid wood, engineered, and composite lumbers, and are utilized in diverse applications. However, one shared truth is that failure to anticipate the specific connection needs of the project can compromise the wooden beams’ stability and lead to subpar safety standards.

This article will explore what you need to know about different types of wood beam connectors, including mechanical and joinery, to help you determine the optimal attachment method for the application.

Looking for concealed beam hangers for your next project? Discover SFS’s line of HVP connectors.

Two major methods of connecting wood beams

When it comes to connecting wood beams in a load-bearing structure, there are two main methods commonly utilized: mechanical and carpentry-based

Mechanical/hardware-based connection method

This first method involves connecting beams using almost entirely of wood or steel hardware consisting mainly of hangers, fasteners, brackets, and plates. and come in either wood or steel. The various hardware options differ in their visual appearances, load-bearing capabilities, and installation processes, making some more suitable for specific projects than others.

Fasteners - Fasteners—like bolts, nails, dowels, and screws—create load points on beams in the area where the fasteners are installed. Although they can be used to connect beams on their own, fasteners are often used in the assembly of other hardware as well, like attaching a plate or hanger to a beam.

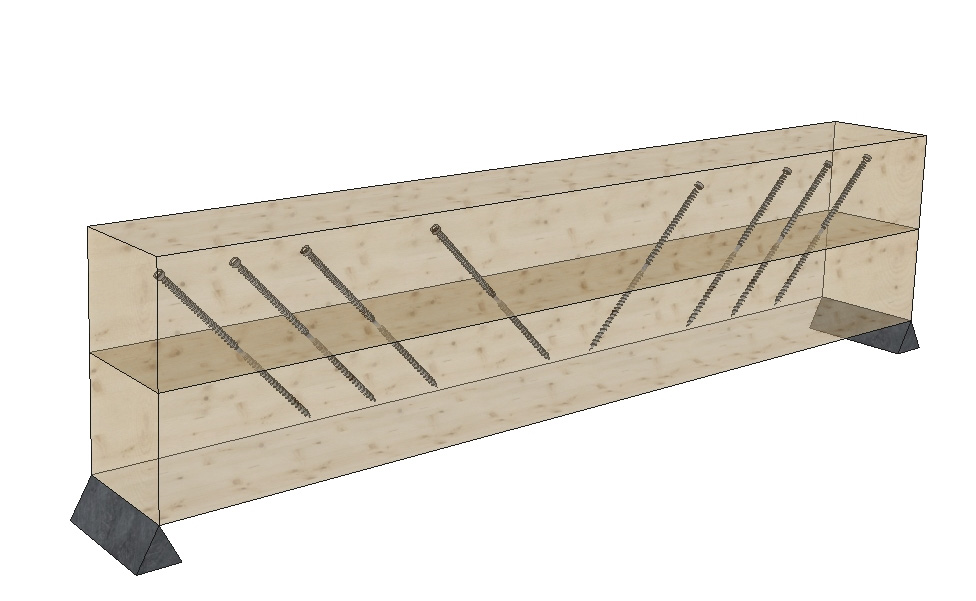

Screws are not only the most common fastener used to connect wood beams, but also arguably the most diverse. Buyers can choose from diverse tips and thread options, such as such as partially or fully threaded, lag or proprietary, etc. If you are unsure about the preferred makeup of the fastener for your specific wood beam connection needs, the SFS team can help guide you towards targeted features that can benefit your project as a whole.

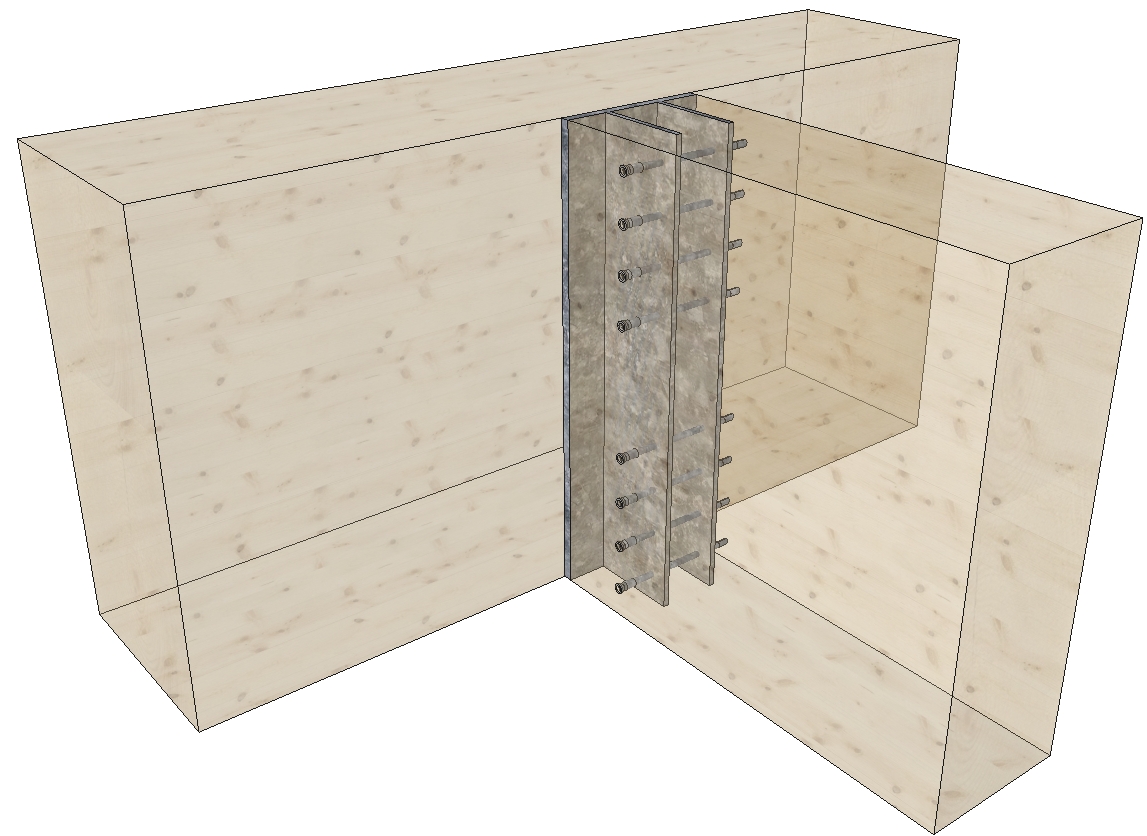

Beam hangers - this specific type of wood beam connection is either concealed (two metal pieces that fit together tongue-and-groove style) or are visible (the beams to fit inside of pocket-like metal shelves). Unlike fasteners, they will distribute the load across the contact surface. (Use photo of concealed beam hanger)

Carpentry-based connection method

The second primary method employed for connecting beams involves utilizing carpentry techniques to modify the beams, enabling them to fit together seamlessly without the necessity of additional hardware.

Assessing mechanical beam connectors versus carpentry-based connectors

These two different methods allow for beams to connect in numerous styles such as end to end, column to column, beam to column, and beam to beam. The specifics of your project will help determine which wood beam connection technique is most beneficial. For example, if there is an end-to-end connection, using hardware like hangers may be more ideal than a carpentry-based connectionI. If you were instead connecting four beams to a post, youwould likely prefer to use a mechanical connection method like plates. Outside of related costs, you should also consider the load requirements, desired aesthetic, and fire rate resistance when deciding between these two connection methodsy

Trouble Shooting Potential issues when connecting wood beams

Since wood beams may be load-bearing elements of a structure, it’s critical to be mindful of potential problems and strategies for mitigating related risks when installing connectors.Failed notching

Notching or bored holes can cause problems, including stress on the beam and even cracking. As a result, areas of high-stress concentration should always follow approved designs and NDS recommendations for proper reinforcement, such as the utilization of properly sized and located fully threaded reinforcement screws.Moisture

When wood beams are not properly protected from moisture, they can swell and contract. Shrinkage can frequently lead to cracks and split wood. Moisture, meanwhile, can lead to significant rotting and decay, greatly affecting the structure as a whole. Whenever possible, wood beams should be appropriately protected from the elements with proper sealant.Still, careful consideration should be taken when selecting mechanical connections when high moisture exposure is expected. Potential changes must be accounted for in the initial design, along with efforts to minimize exposure to the elements. For example, regular exposure to moisture and other corrosive conditions would lead us to recommend the use of stainless steel fasteners or fasteners coated with a system that performs the same as Hot Dipped Galvanizing (HDG). If your hardware is considerably exposed to factors like moisture or chemicals, stainless steel fasteners are highly recommended. An example of this would be if you are fastening into oak; Since this type of wood contains a sap known for causing corrosion, you will want to opt for fasteners that are more corrosion- resistant.

Hydrogen Embrittlement

Hydrogen can become trapped inside a fastener or within a fastened beam, causing what is known as hydrogen embrittlement or hydrogen-assisted cracking. When this happens, a fastener's ductility will decrease and, as the name suggests, it becomes brittle and breaks very easily. It is important that you research and ask questions to your fastener supplier about whether they use preventative processes that ensure their products are hydrogen-free. If the fasteners have not been heat treated to remove hydrogen, they will break once under tensile stress rather than be successfully load-bearing. Read more about how to detect and prevent hydrogen assisted stress corrosion cracking.

HVP connectors from SFS

As an industry leader continuing to evolve construction possibilities through ongoing innovation, SFS’s line of concealed beam hangers are optimal for mass timber wood connections. SFS is invested in inventing success together with their customers by collaborating to develop and supply solutions fit for all of their projects. They commit to quality through rigorous testing and a deep understanding of the products they supply.

Consider the following options for your next wood joinery project, all engineered for success.

- Heavy-duty HVP connectors are made of anodized aluminum and used for main-secondary beam joints or beam column wood-to-wood joints

- HVP connectors designed for main-secondary beam joints come with holes at optimal distances to the edges, and variable screw lengths ensure accuracy of fit for each timber section.

- HVP connectors with uplift protection feature disposed inclined drilled holes, along with compatibility to different screw lengths, protecting against uplift from the elements.

Leverage the optimal wood beam connectors for your project

Selecting the right wood beam connectors is a critical decision in any woodworking project. The wrong choice can detrimentally impact construction and create safety hazards, from splinting to rotting wood, expansion or shrinkage.SFS prides itself on being more than a manufacturer; we are also our customers’ strategic partner, consulting about ideal wood beam connectors, fasteners, and other construction considerations. If you are unsure about which wood beam connectors are right for you, members of the SFS team are ready to help. Call 610-376-5751 to consult with a specialist.

FAQ about wood beam connectors

1. What are signs that custom connection solutions are required for my project?

The architects, specifiers, and designer and structural engineers “dictate” the type of wood beam connections that will be used for a given project. If they decide that a high-load connection is involved, this is a common indication that a custom-specific solution may be required. In common residential framing connections, many manufacturers have standardized connection details. In the best case, please get in touch with your supplier for the proper assistance.

2. Are there any building code considerations when using wood beam connectors?

All wood beam connections should comply with the National Design Specifications (NDS) for the wood construction, in accordance with the local building code.

3. Should the type of timber I use play a role in the choice of beam connection or joinery I choose?

Depending on the density of the wood species, some specific considerations may be required such as whether or not to pre-drill, usage of connection hardware, reinforcement requirements, etc.

English (Canada)

English (Canada)

čeština (Česká republika)

čeština (Česká republika)

magyar (Magyarország)

magyar (Magyarország)

Deutsch (Deutschland)

Deutsch (Deutschland)

eesti (Eesti)

eesti (Eesti)

español (España)

español (España)

português (Portugal)

português (Portugal)

suomi (Suomi)

suomi (Suomi)

français (France)

français (France)

English (United Kingdom)

English (United Kingdom)

italiano (Italia)

italiano (Italia)

Nederlands (Nederland)

Nederlands (Nederland)

norsk, bokmål (Norge)

norsk, bokmål (Norge)

polski (Polska)

polski (Polska)

svenska (Sverige)

svenska (Sverige)

Türkçe (Türkiye)

Türkçe (Türkiye)