Corrosion prevention: methods to protect building structures from environmental damage

Corrosive damage is pertinent to all construction jobs and should therefore be accounted for during the design phase of any project. Often observed as "rust", corrosion is the progressive deterioration of metals through an oxidation process. In practice, corrosive damage results in an unpleasant building appearance, compromises structural integrity, and damages internal building structures. Fortunately, proper project planning can absolve architects, designers, and contractors of these potential issues.

Scroll down to watch our "Guide to corrosion" video!

Strategic material selection to prevent corrosion in building structures

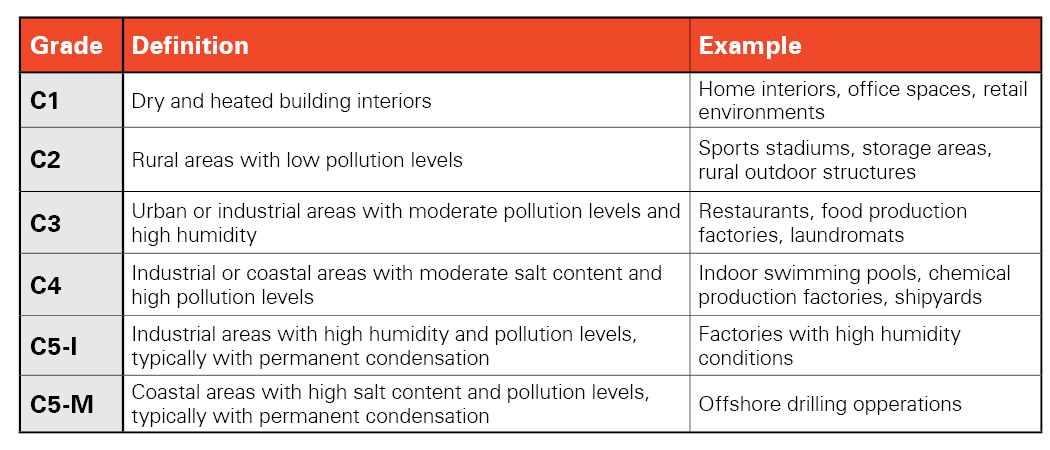

Corrosion is precipitated by environmental factors like humidity, air salinity, and chemical content. However, the use of certain materials can limit or completely negate damage introduced from these conditions.Strategic utilization of rust-resistant steels

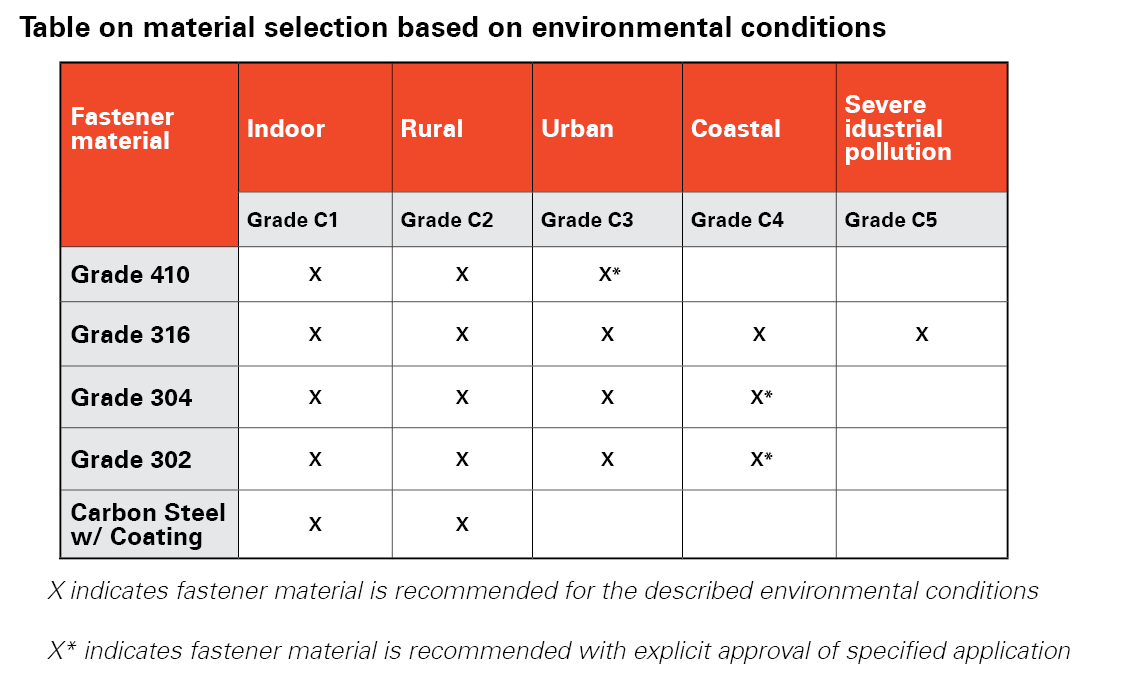

Iron and steel are ubiquitous components in nearly all construction jobs. However, some alloy steels have limited corrosive resistance due to their high carbon content. Selecting a steel alloy with low carbon content, such as 300 series stainless steel, can diminish the chances of corrosive damage. Note, however, that as the corrosive resistance of a material is improved, its structural strength characteristics decrease and its cost tends to increase. For this reason, construction projects with less demanding needs for corrosion prevention often opt for the more affordable (but less effective) 400-series stainless steel. See below for more information on defining your locations corrosion class.

Application of protective exteriors

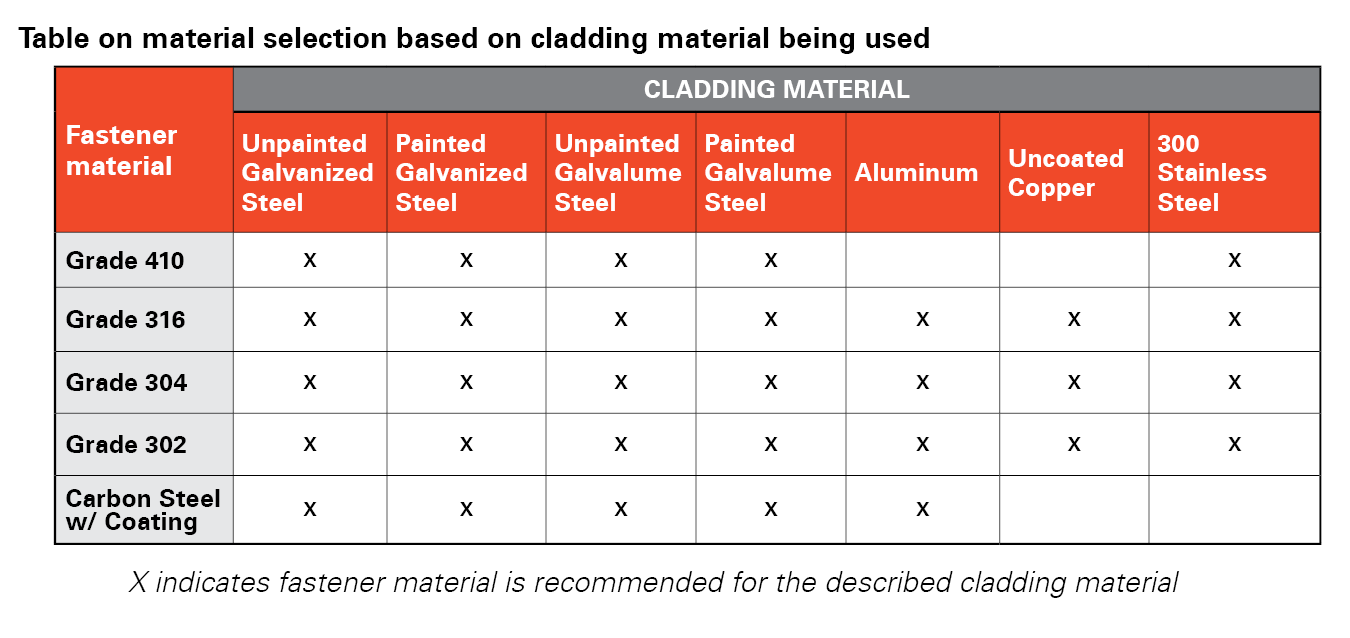

To decrease cost but improve rust protection in harsh environments, a number of different coatings can be applied to (typically steel) building components to prevent corrosion. One method, called galvanizing, applies a thin layer of zinc or magnesium to steel components. This coating will sacrifice itself to protect the structural integrity of the base component.While this sacrificial property of metals can be exploited to extend the lifetime of certain parts, it can also work adversely if not considered when dissimilar metals are in contact. Known as galvanic or bimetallic corrosion, dissimilar metals, when in contact with each other and an electrolyte like water, will cause one material to rust faster than the other. Most commonly, this type of damage is seen when steel and copper are in contact on the exterior of a building, but many other combinations can also cause corrosion. The chart below can be utilized to determine which metals can safely be used in conjunction.

Construction methods to prevent corrosion

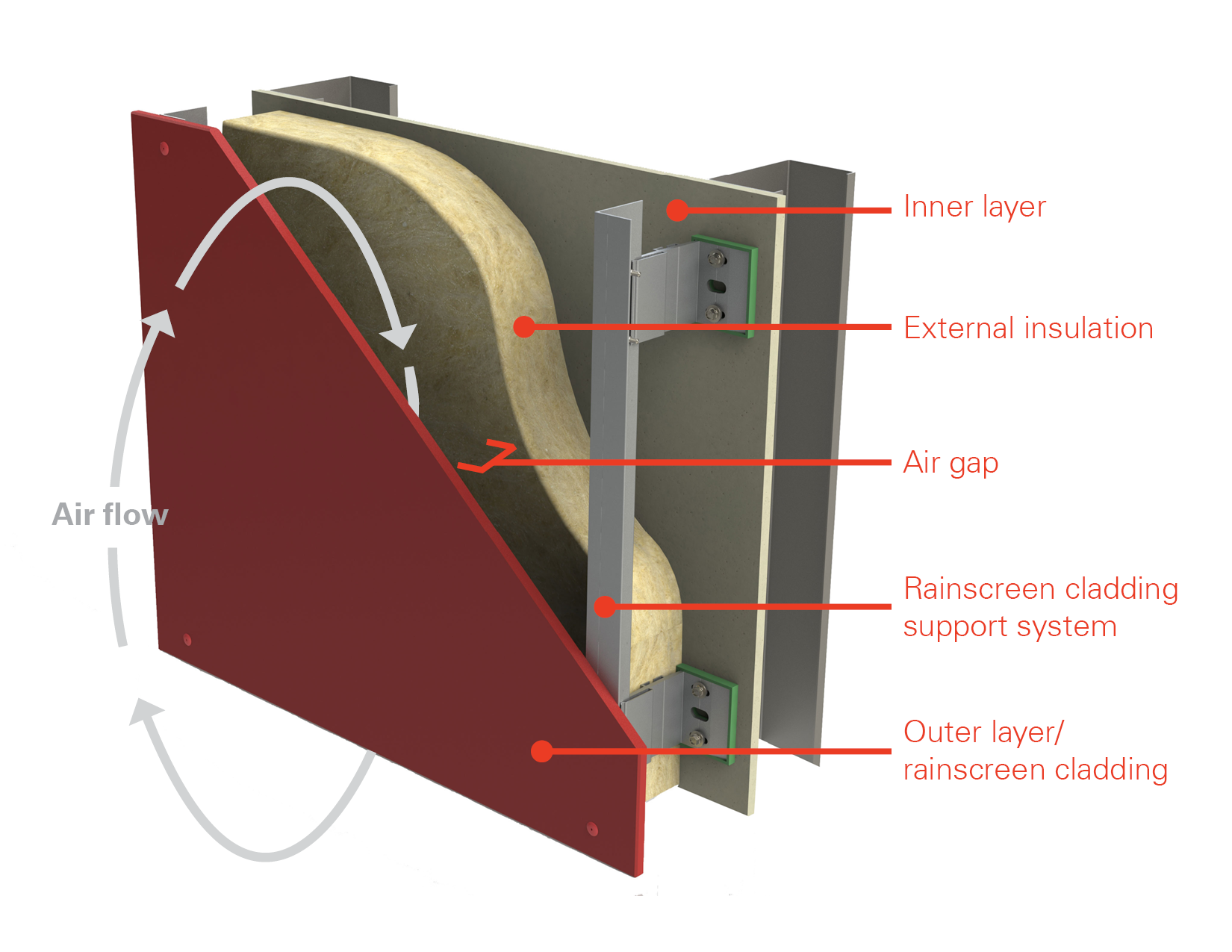

The construction industry recognizes the critical need to prevent corrosion for long-lasting and structurally sound buildings. By employing advanced construction methods, such as rainscreens and protective rust-proof top coats, builders can effectively counteract the damaging effects of corrosion. These methods serve as effective solutions in safeguarding structures, strengthening their durability, and extending their lifespan.Rainscreens

A rainscreen is an assembly applied to an exterior wall that consists of at minimum, an outer layer, an inner layer, and an airspace between them. They have become increasingly important in commercial construction due to the complexity of exterior wall assemblies and the need for continuous control layers. They are effective in managing moisture and providing an integrated approach to maintaining a dry and durable building.

Rainscreens can help prevent corrosion in commercial construction by managing moisture and creating a protective barrier between the exterior cladding and the underlying wall assembly.

Moisture is a major contributor to the corrosion of metal components in structures. Rainscreens are intended to control moisture by forming a gap or cavity between the exterior layer of cladding and the inside layer of wall assembly. This gap enables the passive removal of liquid water and water vapor. Rainscreens can help lessen the danger of corrosion by reducing how much rainwater meets metal components.

Check out our article “What is a rainscreen” for more in depth information!

Protective rust-proof top coats

Many components can also be specified with a rust-preventative top coat. These come in a myriad of types with varying properties. Epoxy coatings provide good strength but are susceptible to color fading. Alkyd enamels have comparable strength but are less susceptible to color damage from UV rays. Polyurethane coatings typically have the best strength characteristics and UV resistance.As coating effectiveness improves, cost also tends to increase. A designer should consider how much corrosion protection is required for the structure, and ensure that the top coat color matches other building components.

SFS VistaCoat® premium system

The VistaCoat® system is a high-performance coating that is corrosion- and UV-resistant, long-lasting, and eco-friendly. The purpose of this system is to offer the best installed product quality.

The VistaCoat® coating is designed to withstand demanding fastener applications. With the use of cutting-edge pigmentation, VistaCoat® offers superior gloss and color retention. The most recent technology is used to apply the coating, adding consistency and protection.

Benefits:

– Superior durability

– Brilliant gloss and color retention

– Innovative pigmentation process

– Enhanced color consistency

– Resistant to effects of UV and corrosive environments

– Isocyanate free

– Environmentally friendly

Warranty inquiries

Some component manufacturers specify warranties on their parts regarding corrosive resistance. It's typically a good idea to ask suppliers about potential warranties, as this is a good indicator of both product performance and supplier confidence.Frequently asked questions about preventing corrosion in construction projects

How can I determine how much corrosion protection I need?

First, it’s important to think of where in, or on the building will the fastener be used. If used on the interior of the building, where moisture is going to be controlled by the HVAC system, corrosion will likely not be much of a concern. For this reason, interior fasteners that will not see any weathering are typically installed with zinc plating or a phosphate coating.

If the fasteners are being used on the exterior of the building, whether it be on the roof or an exterior wall, then much more thought should be put into the corrosion of the fasteners. For exterior fasteners, the application of the connection and the location of the building are the driving factors in corrosion potential. While uncommon, even the contents on the interior of the building can cause corrosion. At a minimum, exterior fasteners should be coated with a zinc-rich coating like VistaCoat. This is generally acceptable for metal panel attachment in parts of the country that are not near the coastline. When the building is closer to the coastline, humidity and salt become a concern, and more corrosion protection is needed. For these applications, capped fasteners are common. Stainless steel and Zinc-aluminum alloys are common materials used to increase the corrosion protection of the heads of fasteners when this extra corrosion protection is needed. When the building gets to within a couple miles of the coast, then considerations should be made to use fasteners that are made from stainless steel, particularly 304 stainless steel which is the most corrosion-resistant and commercially available alloy of stainless steel. ‘

Stainless steel should also be considered in Rainscreen applications where moisture is considered to be always present, as well as in aluminum applications to help prevent galvanic corrosion.

What are early signs of corrosion caused by weather?

The discoloration is the first sign that corrosion is happening. For a fastener that is zinc plated, or that has a zinc-rich coating, white rust will likely be the first sign of corrosion. White rust is what happens when the zinc is sacrificing itself and corroding. This can happen quickly, and is why zinc plating is often referred to as a sacrificial coating. White rust in and of itself is not necessarily cause for alarm. However, white rust often precedes red rust, which is a sign that the fastener itself is corroding. Red rust is caused by the iron in the steel fastener oxidizing into iron oxide. The problem with red rust is that it’s effectively removing the iron from the steel, and over time this can cause fastener or connection failure. If you’re seeing red rust, it’s likely because the fastener that was installed was not selected correctly, and fastener replacement with more corrosion protection should be considered.

At what degree of corrosion does a fastener need to be replaced?

It is critical to assess the kind and severity of corrosion present. In general, if a fastener has substantial pitting corrosion or rust that threatens its structural integrity, it should be replaced to guarantee the application's safety and dependability. Understanding the elements that lead to fastener corrosion, such as incorrect coating, ambient conditions, and material compatibility, can also aid in determining the need for replacement.

Be sure to replace with the correct fastener, more info here! Replacing metal roof screws

What are the most common and most detrimental pollutants that contribute to corrosion in buildings?

Urban and industrial atmospheres, sulfur dioxide pollution, coastal areas, high humidity environments, chemical manufacturers, areas with permanent condensation, sulfur dioxide pollution, coastal areas, high humidity environments, chemical manufacturers, areas with permanent condensation.

What is the most economical way to prevent corrosion in existing buildings?

Proper Installation: Ensure that all building components are installed correctly and in compliance with industry standards to prevent moisture infiltration that can lead to corrosion.

Choosing the Correct Fastener and Coating: Select fasteners and coatings that are suitable for the building's location and environmental conditions to mitigate the risk of corrosion.

Proper Storage: Store fasteners in a dry environment, shielded from moisture and direct exposure to the elements to maintain their integrity and reduce the risk of corrosion.

Regular Inspection: Conduct routine inspections of fasteners to identify and address early signs of rust promptly to prevent further damage or deterioration.

Early Intervention: Addressing corrosion early is more cost-effective than dealing with the consequences of severe damage, such as a collapsed roof. Timely detection and intervention can help prevent costly repairs and maintain the structural integrity of the building.

What are the most (and least) corrosion resistant construction materials?

When looking at the material with the most corrosion resistance stainless steel is at the top: particularly 316 stainless steel, with its added molybdenum content, which is commonly used for coastal applications due to its high corrosion resistance. On the other hand Carbon steel is among the least corrosion-resistant materials and is susceptible to rusting over time.

Does the prevention of atmospheric corrosion require different methods than that of weather-based corrosion?

While there can be some overlap in the preventive measures for atmospheric and weather-based corrosion, the specific methods employed may differ to address the unique factors involved in each type of corrosion process. The prevention methods for atmospheric corrosion, such as coatings and corrosion-resistant alloys, focus on creating a barrier between metal surfaces and corrosive pollutants in the air. Weather-based corrosion prevention involves strategies to minimize exposure to weathering elements, such as proper drainage, sealants, and selecting weather-resistant materials.

Determine the appropriate level of rust prevention with insights from SFS

Consult with the product managers and engineers of SFS about which fastening and rainscreen solutions provide the necessary protection from corrosion. We can recommend solutions that account for the intended part utility, budgetary restraints, and environment.Contact SFS by calling (610) 376 5751.

English (Canada)

English (Canada)

čeština (Česká republika)

čeština (Česká republika)

magyar (Magyarország)

magyar (Magyarország)

Deutsch (Deutschland)

Deutsch (Deutschland)

eesti (Eesti)

eesti (Eesti)

español (España)

español (España)

português (Portugal)

português (Portugal)

suomi (Suomi)

suomi (Suomi)

français (France)

français (France)

English (United Kingdom)

English (United Kingdom)

italiano (Italia)

italiano (Italia)

Nederlands (Nederland)

Nederlands (Nederland)

norsk, bokmål (Norge)

norsk, bokmål (Norge)

polski (Polska)

polski (Polska)

svenska (Sverige)

svenska (Sverige)

Türkçe (Türkiye)

Türkçe (Türkiye)