OSB Screws — SFS Best Picks & Fastener FAQ

Oriented strand board consists of wood flakes and strands pressed into large boards using water-resistant adhesive. The result is an affordable engineered wood stronger than plywood and practical for a variety of interior sheathing projects including roofs, floors, and walls.

While it’s hard to find fault with OSB, there are special considerations for which builders should account. Mainly, when compared to other engineered woods, it presents an increased likelihood of splitting or for stripped fasteners. Therefore, it’s best to use screws specifically designed for OSB to significantly lessen such risks.

What to look for when choosing screws for OSB

The best way to minimize the potential for stripped fasteners is by employing screws with aggressive threading. This references a higher thread pitch (the distance between two threads). The lower the threads-per-inch (TPI), the deeper the ridges and greater the fastener grip. For instance, let's compare the #10 Woodgrip™ HiLo with an OSB screw like the #12 Woodgrip™ XG. The former has 15 threads per inch while the latter has only eight.The aggressive threading ultimately leads the screws to produce greater pull out strength when connecting OSB sheathing. Revisiting the #12 Woodgrip™ XG, it can withstand an impressive 412 pounds of force.

Other considerations when choosing the best OSB screw

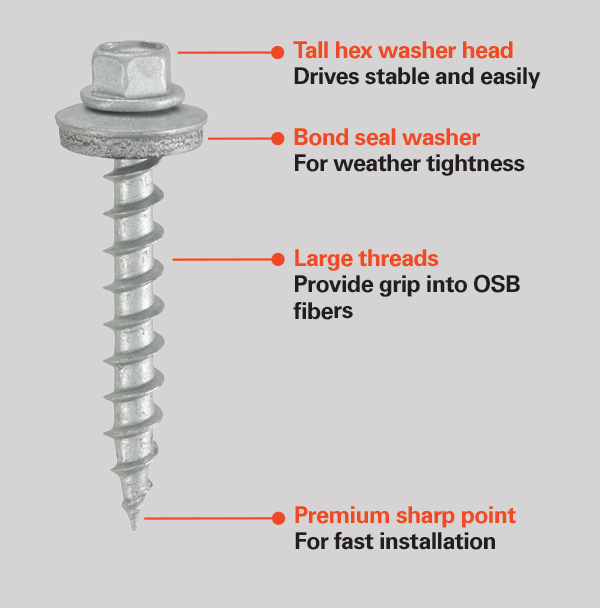

● Sharp point for self-drilling. A sharp point enables smoother piercing of the wood and less physical pressure needed when applying.

● The type of fastener head. There is no one style of screw head that is objectively best for OSB construction. While a tall hex washer head provides added stability during the application, countersunk alternatives lay flush with the OSB, making it ideal for subfloor applications.

● Rust resistance. Warping due to moisture exposure is considered the Achilles' heel of OSB, so it’s rare for builders to use it for exterior applications. However, there are lesser-known OSB board options with high water resistance, leading to some contractors bucking tradition and featuring OSB in ways that expose it to weather. In such cases, you will want fasteners that offer inherent rust resistance.

SFS picks for our best OSB screws

#12 Woodgrip™ XG- If we were to recommend a single screw for OSB, it would be the #12 Woodgrip™ XG. Calibrated to fit most OSB and plywood construction needs, its purpose-driven aggressive screw design yields strip out value ratings 30% greater than those of standard wood screws. A sharp point combines with a tall hex washer head for easy, smooth self-tapping without the risk of over-drilling. This OSB screw is also suitable for outside use, thanks to its weathertight washer and protective VistaCoat® premium coating that wards off the effects of UV rays and moisture.

#14 Type 17 A-Milled Point- Another member of the Woodgrip metal-to-wood fastener family, this fastener also offers the aggressive thread design necessary for screwing into OSB. It shares many other characteristics with the above-mentioned #12 Woodgrip™ XG, including the bond seal washer and VistaCoat® premium coating system. The biggest difference is the greater gauge diameter which accommodates even more weight than its smaller alternative. However, contractors will find that the #12 Woodgrip™ XG is suitable for most OSB connections, making related costs for the larger gauge unnecessary for many projects.

#12-8 WoodZAC® XG Metal to Wood Fastener- A close cousin of the two OSB screws above, this member of the WoodZAC® family stands out for its zinc alloy cap head designed to combat damaging moisture and corrosive elements. Count on the #12-8 WoodZAC® XG for harsher exterior applications.

#15 Phillips Head DF-#15-PH3 - Hailing from the widely celebrated Dekfast™ product line, engineers designed this fastener with ease of use in the forefronts of their minds. Even beginning contractors can fasten with confidence thanks to its stability-producing #3 Phillips drive and powerful drill point. The screw’s premium-level strength and cathodic epoxy e-coat make it a popular choice for OSB, metal, and even concrete.

FAQ about OSB screws

Can I use other wood screws with OSB?The short answer to this question is that, yes, you can fasten OSB with other types of wood screws. However, you increase the chances of splitting wood and stripping screws, leading to compromised connections. Click here for more recommendations about picking the ideal wood screw.

Do OSB screws work for other types of wood?

Screws intended for OSB satisfy the similar needs of other softwoods, like plywood and pine. However, they’re not the best choice for hardwoods which may be best served by fasteners with less aggressive threading. To learn more about your options, read 'Fine thread versus coarse thread'.

How do screws compare to nails for OSB?

Typically, screws are best for OSB and softwoods due to the heightened chance of splitting and easier removal at a future date. This results in a weaker connection and can damage the integrity of the subfloor or sheathing. Plus, OSB subfloors applied with nails rather than screws are more likely to creak.

WGP-#10x2-1/2-CS1/2-V0091-F

Item No.

1781109

WGP-#10x2-1/2-CS1/2-V0696-F

Item No.

1781108

WGP-#10x2-1/2-CS1/2-V1210-F

Item No.

1781107

WGP-#10x2-1/2-CS1/2-V0102-F

Item No.

1781106

English (Canada)

English (Canada)

čeština (Česká republika)

čeština (Česká republika)

magyar (Magyarország)

magyar (Magyarország)

Deutsch (Deutschland)

Deutsch (Deutschland)

eesti (Eesti)

eesti (Eesti)

español (España)

español (España)

português (Portugal)

português (Portugal)

suomi (Suomi)

suomi (Suomi)

français (France)

français (France)

English (United Kingdom)

English (United Kingdom)

italiano (Italia)

italiano (Italia)

Nederlands (Nederland)

Nederlands (Nederland)

norsk, bokmål (Norge)

norsk, bokmål (Norge)

polski (Polska)

polski (Polska)

svenska (Sverige)

svenska (Sverige)

Türkçe (Türkiye)

Türkçe (Türkiye)