Screw pull-out strength: What to consider & calculate

In construction, you never want to your work to fail, as it can be dangerous and costly. During projects of all types, there are many factors to consider to ensure your work is structurally sound and protected from the elements.

One critical factor to consider when selecting screws is pull out strength. Without keeping this in mind, a strong gust of wind could pull your metal roof off or result in a loading bearing beam giving way.

What is pull out strength?

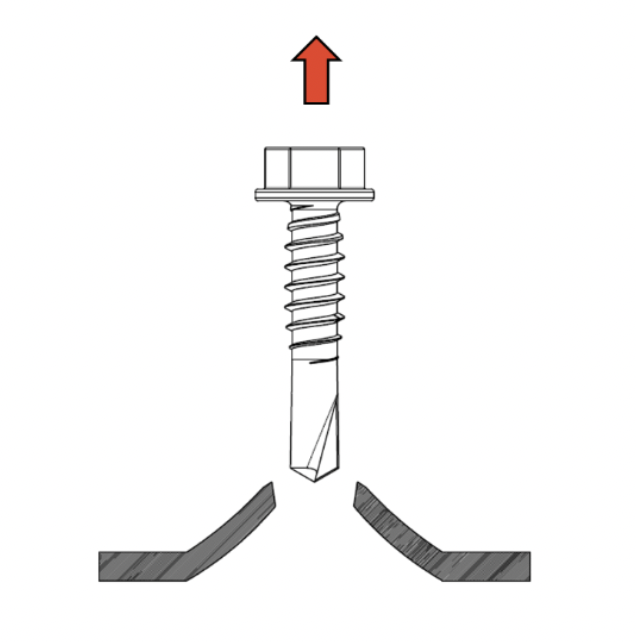

Screws and other fasteners have a calculated pull-out strength, which defines how much force they can withstand, on average, before being pulled out or the head of the screw breaks.Pull out strength is considered in any construction scenario, whether you are conducting internal or external work. Based on the location of the fastener and the forces acting on it, different levels of pull-out strength will be necessary.

For example, when selecting a fastener for an external beam, you will need especially strong pull-out strength. External beams have the force of gravity from cross beams and outsider weather factors they must withstand. Using a fastener with strong pull-out strength ensures your joint can withstand those forces.

Similarly, when building a metal roof on a barn, you risk a strong wind gust pulling the entire roof off. Constrastly, an everyday handrail won't require as much pull-out strength since the force acting on it will be much smaller.

How is a screw's pull out strength calculated?

At SFS, we rigorously test all fasteners to confirm peak performance. After testing over various batches of screws and fasteners, we calculate standard average measurements you can reference when selecting parts.We leverage a tensile test puller to calculate pull out strength for fasteners. This procedure is completed by fastening the screw to the material that is planned to be used on the job site in question. The fastener is then placed through a plate with a hole in the middle, which is anchored down to the base of the tensile tester.

A jaw block with a u-shaped cut out is secured around the head of the fastener, which is attached to the moving portion of the tensile tester. Then, force is applied, pulling the fastener through the material until all threads are no longer engaged or the fastener itself fails, resulting in a break.

How does thread engagement relate to a screw's pull-out strength?

When calculating pull-out strength, you also need to consider the length of the screw and the thickness of the material you’re screwing into. These both factor into thread engagement. Greater thread engagement will increase pull-out strength due to greater gripping force.If you’re constructing a building’s framework, you don’t want screws to poke through the wood, so you need to consider the thickness of your material. If you have 3” to fasten, it will be best to use a 2-½” screw to maximize thread engagement without going all the way through the material. If you only have 2” to fasten, you may use a 1-½” long screw that’s wider, to increase the surface area of threads engaged.

Discover how to choose the correct screw length for your project.

What should be considered during fastener selection?

There isn’t a one-size fits all answer for your projects. Instead, when selecting fasteners for your projects, there are various factors to consider with regard to pull-out strength:- External forces acting on the fastener

- Type of material to be drilled into

- Depth of material

Learn about the varying levels of corrosion resistance offered by different stainless steels by reading 300 vs 400 stainless steel and 304 vs 316 stainless steel screws.

If you anticipate your office flooring material being under a high amount of load, for example, large furniture, you will want a thicker fastener to maximize thread engagement.

Next, you’ll consider what you’re drilling into. In this case, you’re using wood planks that are 4” thick. In that scenario, you’ll want to leverage a screw 3 to 3½” thick to optimize thread engagement.

Keeping all of these factors in mind during fastener selection will help to ensure that your work does not fail under reasonable circumstances

Select fasteners with the correct pull-out strength with the help of SFS

It’s critical to consider pull-out strength when selecting fasteners for your construction projects — both internal and external. Ensure you evaluate the various factors impacting the required pull-out strength of your fastener early on.Equally as important to your commercial build is finding a trusted manufacturer to deliver premium-level screws while accommodating your projects’ constraints. At SFS, we pride ourselves on being an industry leader that continues to evolve what's possible through ongoing innovation. What's more, we can serve as strategic partners, consulting about necessary pull-out strengths and other construction considerations.

If you’re still unsure about what level of pull-out strength is required for your project, members of the SFS team are ready to help. Call 610-376-5751 to consult with a specialist.

English (Canada)

English (Canada)

čeština (Česká republika)

čeština (Česká republika)

magyar (Magyarország)

magyar (Magyarország)

Deutsch (Deutschland)

Deutsch (Deutschland)

eesti (Eesti)

eesti (Eesti)

español (España)

español (España)

português (Portugal)

português (Portugal)

suomi (Suomi)

suomi (Suomi)

français (France)

français (France)

English (United Kingdom)

English (United Kingdom)

italiano (Italia)

italiano (Italia)

Nederlands (Nederland)

Nederlands (Nederland)

norsk, bokmål (Norge)

norsk, bokmål (Norge)

polski (Polska)

polski (Polska)

svenska (Sverige)

svenska (Sverige)

Türkçe (Türkiye)

Türkçe (Türkiye)