Standing seam comparisons: Snap lock vs mechanically seamed roofing

Mechanically seamed and snap-lock roofing share a number of similarities but their key differences make them best for different scenarios. This article will explore common standing seam systems, snap-lock vs mechanical. We will divulge their individual pros and cons, optimal scenarios for installation, and other factors to consider when making roofing decisions.

Snap-lock:

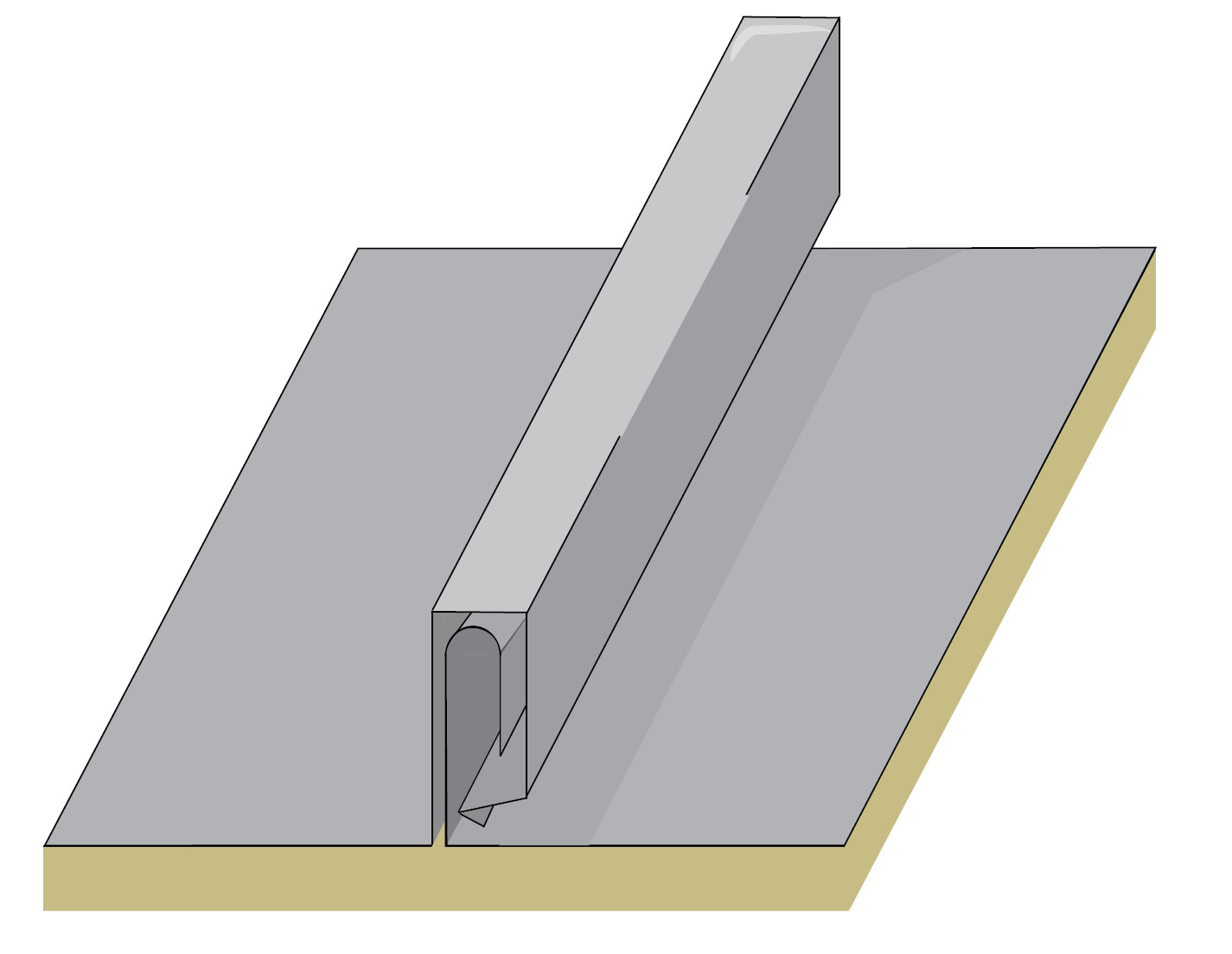

Snap-lock metal roofing is a type of standing seam roof in which the seam is held together by clips that have been screw fastened directly to the substrate. The individual panels of this roof style have a male and female leg on opposite sides which allow all the panels to snap together.Pros:

- Easier to install, no seaming required

- Economical solution

- Weather Tightness

- Concealed fasteners

- Secure and durable

Cons:

- Not as weather-proof as mechanical seam

- Fixed system, no thermal expansion/contraction capacity

Mechanically seamed:

Mechanically seamed roofs also use clips. However, whether these clips are fixed or float clip variations, this system requires an additional seaming operation. Thus, this standing seam style offers a secure weather tight seam and better wind uplift ratings. Mechanically seamed roofs can be single or double-locked; folding the material once (single lock), or twice (double lock) as seen from the mechanically seamed GIF.Pros:

- Strongest weather tight seal

- Can be placed on nearly any roof slope

- Best wind uplift values

- Fixed clip variation used in shorter panel runs

- Float clip variation allows for thermal expansion and contraction

- Best suited for areas with extreme temperature fluctuation

- Requires the use of a seamer

- Additional time and labor needed to install

- Can be more expensive

Snap-lock vs. Mechanically seamed roofing: when is each type optimal?

Both snap-lock and mechanically seamed metal roofs are designed for commercial use. Snap-lock metal roofing is recommended in projects with short panel runs and slopes greater than or equal to 3:12. Snap-lock roofing should also be used in environments without extreme weather conditions.

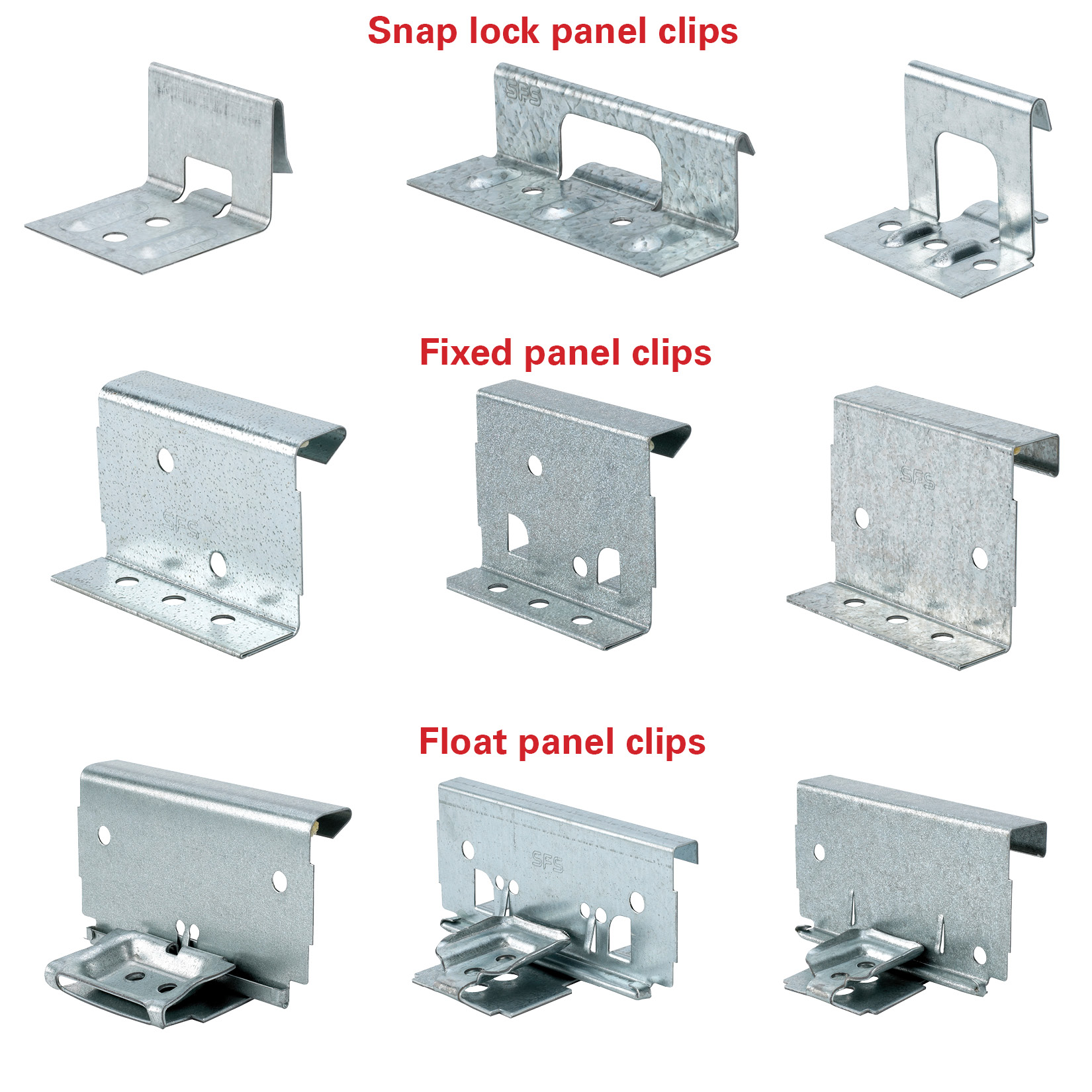

Meanwhile, mechanically seamed roofs can be used on low slopes (0 to 3:12) and on slopes above 3:12. When used on low-sloped roofs, it’s recommended to double-lock seams. Additionally, mechanically seamed roofs are optimal under harsh weather conditions and can be used on both longer and shorter length panels. Shorter length panels typically use a fixed clip. Which means exactly what it says: the clip is fastened at the fixed points and does not allow for thermal expansion and contraction. Contrast to this, the longer length panels require movement and as such require the use of the float clip version.

Options beyond standing seam

An alternative to standing seam metal roofing is a through-fastened, otherwise referred to as "screw down" roof system. While this is the most economical option, it is not recommended for commercial applications due to it being the least-weather-tight. We discuss this more thoroughly in our guide to exposed or concealed roofing fasteners.

One of the main differences between standing seam and screw down roof systems is the lifespan. In fact, through-fastened (screw down) metal roof is not designed to last as long as standing seam roofs. A through-fastened roof's life span is about 20-30 years, while standing seam roofs can last 50+ years. It is important to note that this long life span is dependent on proper installation.

What should be considered when selecting a roof type?

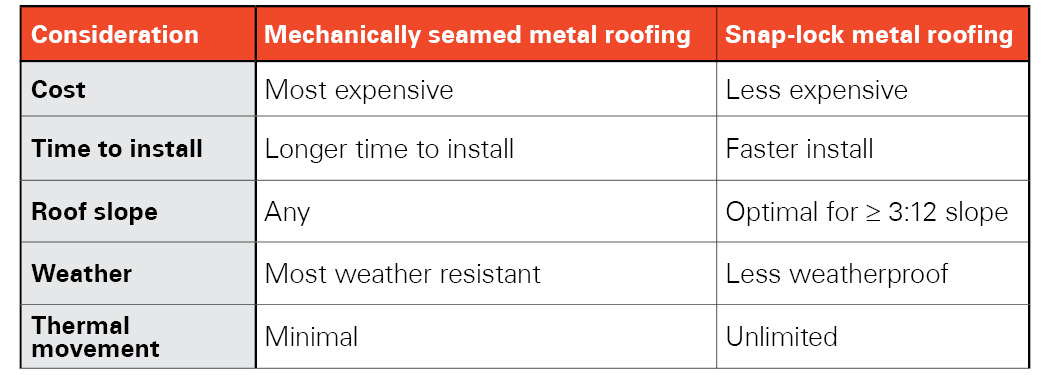

Cost, installation time, roof slope, and weather conditions are key factors when comparing mechanical seam to snap lock roofs.

Which roof type is more affordable?

Snap-lock metal roofing tends to cost less as they don’t need a seamer to install. Meanwhile, mechanically seamed roofing costs more due to the extra time it takes to install and the required seaming equipment.

Which type of metal roofing is optimal for harsh weather conditions?

Mechanically seamed metal roofing is the most weather-resistant metal roofing option on the market. Snap-lock metal roofing is less weather tight when compared to mechanically seamed options but is a better option than a through-fastened roof.

How do the seam types compare when it comes to thermal movement?

Mechanical seam fasteners should only be used where there is minimal differential movement of the roof panels. Meanwhile, snap-lock roofs allow unlimited thermal movement.

Which roof type can be installed fastest?

Snap-lock metal roofing can be installed faster as it requires less tooling. Mechanically seamed roofs take longer to install as they require the use of a seamer. Double-lock mechanically seamed roofs will take even longer to install than their single-lock counterparts.

Discover SFS solutions for all your roofing needs

SFS provides unparalleled metal roofing clips for all types of metal roof systems. For mechanically seamed roofs, we offer L-shaped clips, which are crimped in place by a seamer. Snap-lock metal roofs leverage spring-loaded clips, which hold the roof in place.

Our American-made standing seam roof clips are designed to surpass industry standards and are available in a variety of steels and gauges. Our panel clip finder makes it easy to determine which panel clips will work with your roll former machine. Learn more about the various metal roof clip types SFS offers and discover which option is best for your next roofing project.For additional guidance on roofing options and best practices, read What to include in a commercial roof maintenance plan and Different types of commercial metal roofing & material options.

English (Canada)

English (Canada)

čeština (Česká republika)

čeština (Česká republika)

magyar (Magyarország)

magyar (Magyarország)

Deutsch (Deutschland)

Deutsch (Deutschland)

eesti (Eesti)

eesti (Eesti)

español (España)

español (España)

português (Portugal)

português (Portugal)

suomi (Suomi)

suomi (Suomi)

français (France)

français (France)

English (United Kingdom)

English (United Kingdom)

italiano (Italia)

italiano (Italia)

Nederlands (Nederland)

Nederlands (Nederland)

norsk, bokmål (Norge)

norsk, bokmål (Norge)

polski (Polska)

polski (Polska)

svenska (Sverige)

svenska (Sverige)

Türkçe (Türkiye)

Türkçe (Türkiye)