What is a rainscreen?

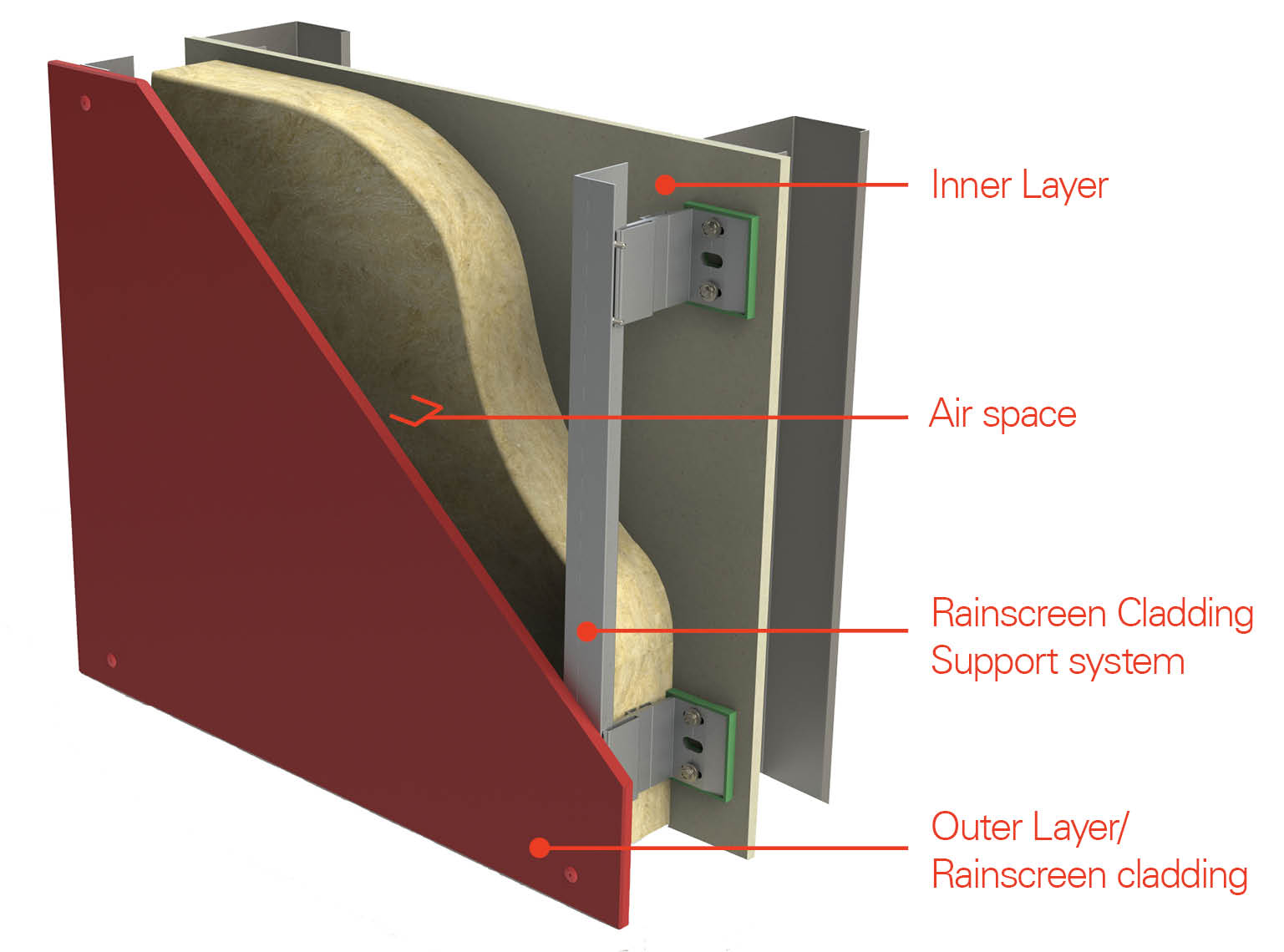

A rainscreen is an assemblage of products whose combined purpose is to promote passive removal of water and water vapor from a building’s exterior. A common misconception is that exterior insulation is an essential element in the overall buildup of a rainscreen assembly. The addition of insulation does have its benefits, but only three elements are required to be considered a rainscreen; an outer layer, an inner layer, and the air space between them

Outer layer

The outer layer of a rainscreen is responsible for shedding a majority of water and preventing its intrusion into the remaining elements. This layer can be made from a variety of different materials, typically called Rainscreen Cladding.Each type has its own benefits and limitations which means care must be taken to ensure the cladding chosen does not negatively impact the entire assembly. For example, some claddings absorb water while others are brittle.

Inner layer

Perhaps the most crucial layer, the materials selected here are the last line of defense for liquid water, water vapor, and air from transferring through the building envelope. Products used here are generally referred to as WRBs (weather-resistive barriers). WRB’s can either prevent moisture from transferring through (vapor barrier), slow the transfer of water vapor (vapor retarder), prevent air from passing through (air barrier), or prevent both air and vapor passage (AVB).

Where and when these products should be used is highly dependent upon the climate zone as well as the distribution of insulation between the wall cavity and the exterior.

Air space

The air space between the inner and outer layer sets a rainscreen apart from other exterior wall buildups. This cavity is essential for the natural process of convection to occur. In simple terms, convection is when hotter air rises which then forces colder air to fall creating a natural wind or movement. The hotter air helps to evaporate the water in the system while the cooler air helps to push any liquid water down the faces of the assembly. Wind from outside the assembly also plays a factor, but not as much as one might think.Are there different types of rainscreens?

Designers have the choice of two types of rainscreen assemblies, either a drain and back ventilated system (DBV) or a pressure equalized (PE) system. A DBV system is designed with an understanding that some water will get past the rainscreen cladding. These systems need venting at the top and bottom of a wall (or run) to allow for air to flow and a place for liquid water to escape. Depending on the project, the air cavity could run continuously or may be broken up at certain heights to place water drainage flashings or mitigate fire concerns.On the other hand, A PE system tries to prevent water from entering the assembly by equalizing the pressure in the air cavity to the exterior environment. Unlike DBV systems, these systems are built as individual assemblies that are compartmentalized and isolated from each other. The size of these compartments is dependent on the environment and wind loads the system will be subject to.

What ties these layers together?

Regardless of what type of rainscreen you design, you will need items that connect the outer surface (rainscreen cladding) to the inner surface and backup wall and are referred to as subframes. The most common subframes on the market are steel girts. However, given the increased thermal requirements in the building code, these traditional methods are becoming less accepted.

There are thermally broken intermittent clip systems that can be made from aluminum, carbon steel, stainless steel, or plastics. These systems offer higher thermal performance while also using less material. Furthermore, the Nvelope aluminum subframe offers additional benefits such as eliminating the need for using shims to level the rainscreen cladding.

Another advantage to a clip and rail system is that they can offer deeper cavities than traditional girts. This provides a huge benefit for those needing additional exterior insulation to meet energy requirements or designers looking to articulate the surface of the rainscreen cladding.

What are the benefits of using a rainscreen?

The addition of exterior insulation can provide substantial benefits to the entire building. For starters, more insulation means that less thermal energy will escape the building envelope. Insulation on the exterior can be run continuously, or close to continuously, limiting direct pathways for energy to thermal bridging. Thermal bridging is when more thermally conductive materials—such as subframes, openings, or trims—provide an easier (direct) path for the energy from inside the building to transfer outside the building. Some insulations, such as mineral wool products, can also provide noise dampening and help mitigate fire spread in cases of emergency.

Rainscreens also provide the designer the ability to pick and choose their exterior finishes. One building could have multiple cladding types that transition into one another or even other wall types such as curtain walls.

Ultimately designing a rainscreen system adds resiliency to your building. When done properly, rainscreens allow for water drainage, prevent water intrusion into the building, promote evaporation, and enable walls to breathe reducing the possibility for mold growth.

What buildings benefit from rainscreens?

All buildings can benefit from rainscreen assemblies as long as they are tailored to meet the specific needs of the environment in which they are placed.Why work with SFS?

Since the 1980s, SFS has designed rainscreen subframes to support cladding systems used all over the world. Our product line, NVELOPE, reflects first-class engineering and efficiency designed to fit your needs. The result? Environmentally friendly rainscreen cladding systems are easy to install and modify for your needs, as well as respectful of your budget.

Why work with SFS for your next rainscreen project?

Since the 1980s, SFS has designed rainscreen subframes to support cladding systems used all over the world. Our product line, NVELOPE, reflects first-class engineering and efficiency designed to fit your needs. The result? Environmentally friendly rainscreen cladding systems are easy to install and modify for your needs, as well as respectful of your budget.

Contact a member of the SFS team with your questions about rainscreen cladding systems or cladding fasteners to learn more.

English (Canada)

English (Canada)

čeština (Česká republika)

čeština (Česká republika)

magyar (Magyarország)

magyar (Magyarország)

Deutsch (Deutschland)

Deutsch (Deutschland)

eesti (Eesti)

eesti (Eesti)

español (España)

español (España)

português (Portugal)

português (Portugal)

suomi (Suomi)

suomi (Suomi)

français (France)

français (France)

English (United Kingdom)

English (United Kingdom)

italiano (Italia)

italiano (Italia)

Nederlands (Nederland)

Nederlands (Nederland)

norsk, bokmål (Norge)

norsk, bokmål (Norge)

polski (Polska)

polski (Polska)

svenska (Sverige)

svenska (Sverige)

Türkçe (Türkiye)

Türkçe (Türkiye)