Washer types: When to use which

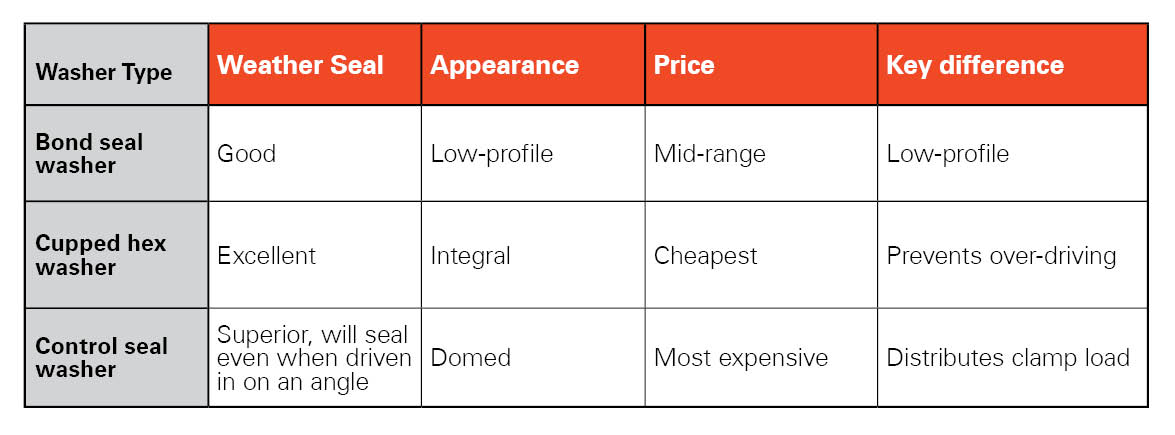

Washer design contributes to the weather tight seal of a fastener. Using the right washer will ensure your building is weather-safe and corrosion resistant. Depending on your commercial project's needs, budget, and other environmental factors, one of three types of washers will be idea. This article will explore the differences between those three types of washers - bond seal, cupped hex, and control seal - to help you determine which is best for your next commercial project.

Which types of washers are commonly used in commercial applications?

Bond seal, cupped hex, and control seal washers are the three main washers for commercial projects. Each washer is made of two key components: rubber and metal. Sealing washer used to be made of neoprene but are now made of ethylene propylene diene monomer (EPDM). All three of these common washer types feature EPDM but in different concentrations which impacts washer performance.

A greater percentage of EPDM in the washer will provide stronger weather protection and a longer lifespan. Meanwhile, washers with less EPDM are more susceptible to cracks and damage, putting the fastener and greater structure at risk of damage and corrosion

The metal portion of washers can be made of galvanized carbon steel, stainless steel, aluminum, brass, copper, or zinc, depending on the desired application and budget.

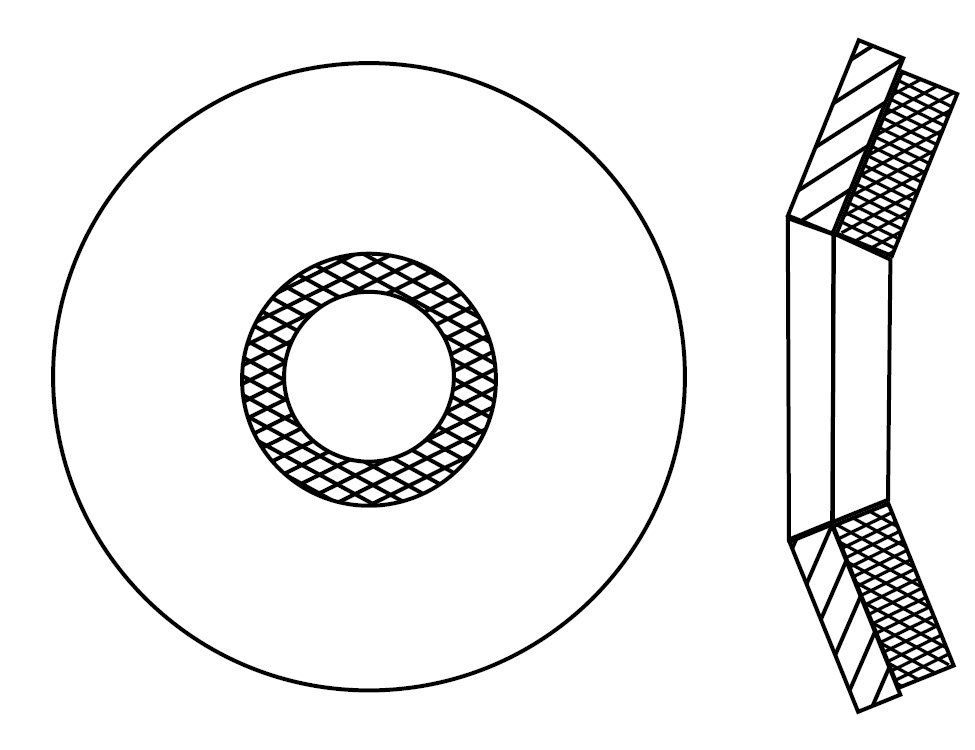

Bond seal washer

A bond seal washer features EPDM rubber bonded to metal. These bonded washers offer a low-profile appearance, allowing them to blend in seamlessly. Bond seal washers provide an excellent weather tight seal between the fastener head and the panel to which they are affixed.Bond seal washers are available in several metal options, including galvanized steel, aluminum, and stainless steel. Depending on the fastener used, the affixing panel, and potential weather conditions, different metal options can minimize corrosion risk.

Bond seal washers are a fantastic option for scenarios where a clean profile is desired without sacrificing a strong weather seal.

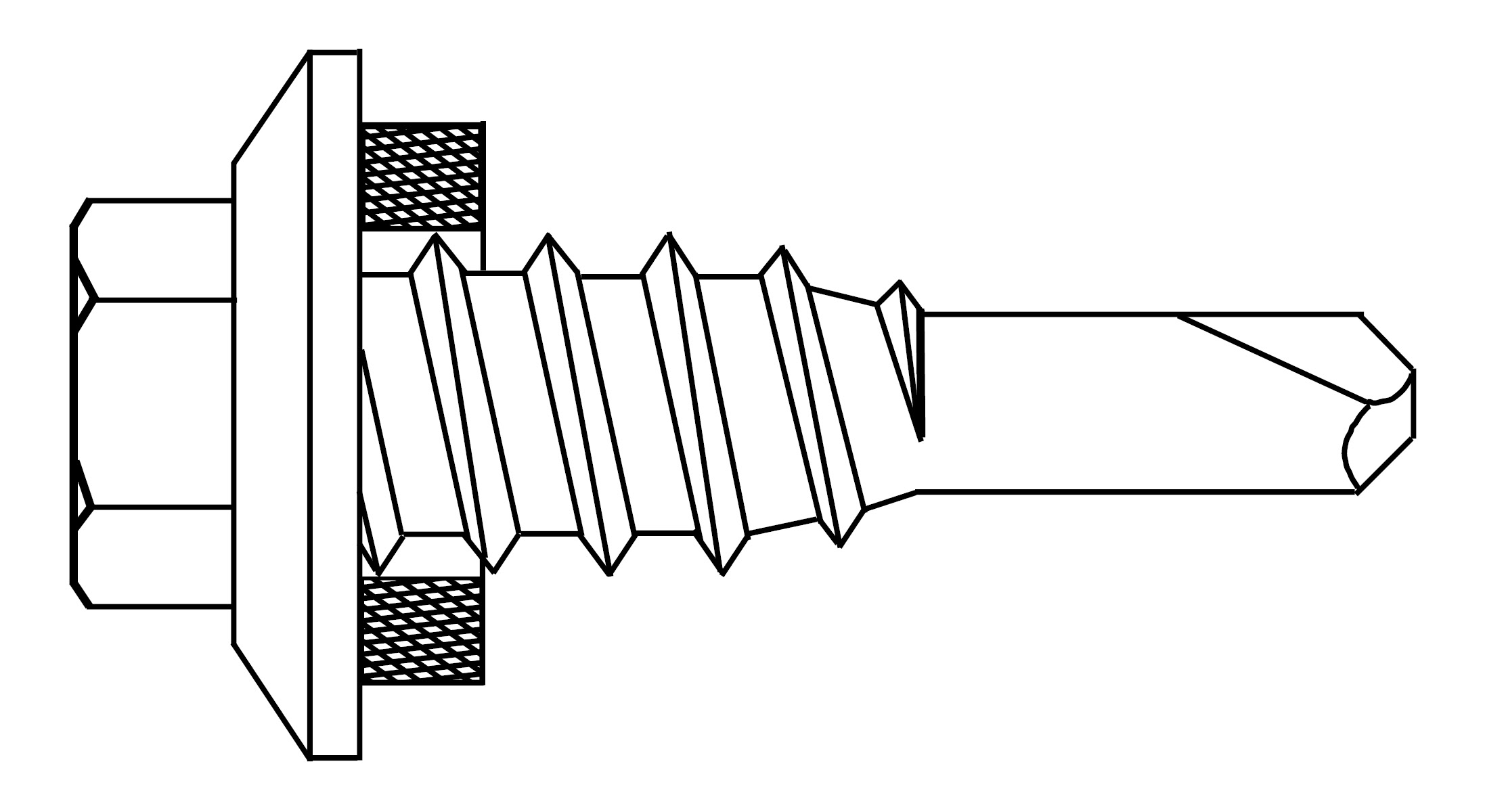

Cupped hex washer

The cupped hex washer head again features EPDM rubber to provoke an excellent weather seal. The cupped washer head design prevents overdriving, making it optimal for use with delicate parts like gaskets that can break under stress.Since the EPDM rubber is underneath the cupped washer head, it is protected from UV rays, which can speed up deterioration. Cupped hex washers are ideal for use with the fasteners that will be exposed to high amounts of UV.

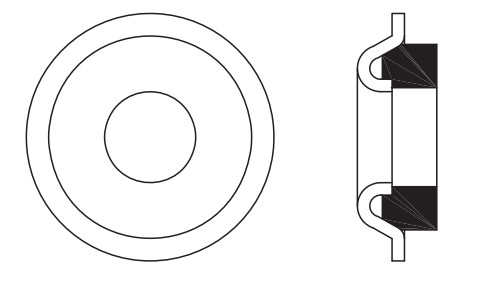

Control seal washer:

In a control seal washer, EPDM rubber is captured under a stamped dome. The EPDM in the washer is compressed in three key areas: against the panel, metal washer surface, and threads. This ensures a sufficient seal.The reinforced dome shoulder distributes clamp load and ensures a weather-tight seal even if the fastener is driven in on an angle. Out of all washer types, the control seal washer is the most forgiving when it comes to installation. Although, proper installation techniques should always be employed.

Which washer type is most cost-effective?

Material play a large role in pricing for washers. Higher quality EPDM washers with longer life spans and better weather protection will be more expensive.Meanwhile, stainless steel washers will be more expensive than galvanized steel but are more corrosion resistant. While galvanized washers are less corrosion resistant than stainless steel, they can offer sufficient protection at a lower price point if your exposure to the elements is limited.

When should you use which type of washer?

All sealing washers provide a weather resistant seal as well as a non-abrasive barrier for vibration damping. Environment, budget, and intended use are the major factors to consider when selecting the correct washer for your commercial project.If your main priority is aesthetic, bond seal washers will be best for your project. Cupped hex washers will minimize the risk of damage if you are working with delicate parts like gaskets or mechanical seals. Meanwhile, control seal washers are most forgiving when it comes to installation and will seal even when installed at an angle.

Which type of metal is best for your washer?

Stainless steel washers are ideal for harsh weather conditions and are especially corrosion-resistant. Our 300-series and 400-series stainless steel washers differ slightly when it comes to composition, performance, and pricing. Explore the "differences between these stainless steels" series 300 and 400.If price is your top priority, galvanized washers will offer good protection against the elements at a lower price point. However, if corrosion resistance is your key concern, you will want to select a stainless steel option.

REMEMBER: Mixing dissimilar metals when combining fasteners and washers can result in corrosions of the fastener and washer, so you should always consider your fastener materials when selecting your washer type.

Explore SFS solutions for your washer needs.

Selecting the right, high-quality washers can prevent leaking, corrosion, and unnecessary wear. Follow these guidelines to ensure you select the best option for your needs. SFS offers several washer options based on the type of fastener and application requirements of your next commercial project. Whether you need metal to metal fasteners, or self-tapping screws in stainless and carbon steels, explore SFS's e-shop, where you are able to filter your search results by thewasher head that you are seeking.

Discover the ZAC®, Bi-Met 300®, and Impax™ lines which are made to maximize strength and combat rust resistance when used with metal washers. If you need to connect dissimilar metals, are installing in a corrosive environment, or are fastening into thick steel beams use SFS's lines of alloyed, bi-metal, and stainless steel self-drilling fasteners.

When reliable installation and efficiency are key concerns, our self-tapping screws in stainless and carbon steels provide unyielding strength and corrosion resistance. Learn more about self-tapping metal screws and their applications.

English (Canada)

English (Canada)

čeština (Česká republika)

čeština (Česká republika)

magyar (Magyarország)

magyar (Magyarország)

Deutsch (Deutschland)

Deutsch (Deutschland)

eesti (Eesti)

eesti (Eesti)

español (España)

español (España)

português (Portugal)

português (Portugal)

suomi (Suomi)

suomi (Suomi)

français (France)

français (France)

English (United Kingdom)

English (United Kingdom)

italiano (Italia)

italiano (Italia)

Nederlands (Nederland)

Nederlands (Nederland)

norsk, bokmål (Norge)

norsk, bokmål (Norge)

polski (Polska)

polski (Polska)

svenska (Sverige)

svenska (Sverige)

Türkçe (Türkiye)

Türkçe (Türkiye)