Comparing Curtain Wall Systems & Rainscreen Installation

Energy efficiency is growing in popularity for commercial construction projects as a strategy to meet net-zero goals and reduce utility costs. As sustainability efforts increase, commercial contractors and operators increasingly turn to green building solutions such as installing curtain walls and rainscreens to improve commercial buildings’ energy efficiency.

While curtain walls and rainscreens can be installed on the same building to work in tandem, they operate independently. Discover the differences between curtain walls and rainscreens, the benefits they provide to commercial buildings, and installation best practices.

Curtain walls

A curtain wall is a non-load-bearing exterior building cover that is installed on commercial structures to reduce the impact of the elements on them. A curtain wall system typically includes an aluminum framework with windows glazed in but can also include lightweight metal panels.

A curtain wall can be used in large-scale building projects (unitized) with easily installed factory-made panels that can span multiple stories or in smaller projects (stick-built) and assembled on-site for shorter lead times.

For large-scale projects, factory assembly provides improved quality control and uniformity. Meanwhile, stick-built panels that are assembled on-site require shorter lead times but more space. However, stick-built curtain wall systems make it harder to maintain consistent panels and require additional on-site labor time.

Why install curtain walls?

Shield structures from the elements

Curtain walls provide protection against the elements, reducing the impact of moisture and wind during storms. Protection against wind is particularly valuable for tall commercial builds, which are increasingly exposed to higher wind loads as the taller they become.

Minimize the impact of fires

Installing a curtain wall system can also provide an extra layer of defense against fires by slowing the speed at which flames can spread from floor to floor.

Reduce ongoing energy costs

Curtain walls can be glazed to reflect light, effectively improving thermal efficiency and reducing energy costs. Engineers have made significant strides in advancing the capabilities of popular curtain wall materials to minimize undesired heat absorption or loss, making today's systems significantly greener than those of past decades.

Enhance the visual appeal

In addition to improving the building's structural integrity and energy efficiency, curtain walls have aesthetic benefits. Curtain wall systems are highly customizable and can be used to improve the exterior appearance of a building, improve natural light inside the building, and otherwise enhance a structure’s visual appeal.

How to install curtain wall systems

A curtain wall is hung using an aluminum substructure installed directly to the building structure. Installation happens after the floor slab or structural steel phase when the building’s skeleton is assembled and in place.

While curtain wall installation typically happens during those early construction stages, it is possible to place a curtain wall onto an existing structure. However, the building must first be inspected to handle additional load, and the old cladding must be removed prior to installing the new system.

It’s essential to also consider factors such as how corrosive the installation environment is, along with whether dissimilar metals will be leveraged. SFS offers several lines of versatile fasteners designed for demanding curtain wall applications as well as design services to meet the unique needs of your project.Rainscreens

While less prevalent on tall buildings than curtain walls in the United States, rainscreens enable superior energy efficiency and moisture management for commercial structures. A rainscreen is any system with a drainage and ventilation space between the inner and outer layers of the exterior wall of the building.

We recommend reading What is a Rainscreen? from the Rainscreen Association in North America for more information.

Why install a rainscreen?

Reduce thermal bridging and improve energy efficiency

A rainscreen is made up of insulation mounted on exterior walls in combination with systems such as thermally broken clips and rails. As a result, rainscreen systems reduce thermal bridging, increasing the overall energy efficiency.

Increase noise insulation

In addition to thermal insulation, rainscreens also provide noise insulation. The diverse materials used in rainscreens reduce noise across a broad range of spectrums. Studies have shown rainscreens can reduce external noise by around 80%. Office buildings benefit from reduced distractions, while warehouses and factories can limit their noise pollution.

Minimize moisture

Rainscreen systems reduce moisture in commercial buildings by allowing any water vapor from inside the building to ventilate to the outside and allow any liquid water that makes it past the panels to drain down to the ground level.

Increase U-Value of older buildings

Rainscreens are particularly good for retrofits on older buildings to increase U-Value. U-Value measures the building envelope’s overall ability to maintain the desired climate inside of the building and is an important design consideration for all building types in all climates.

The primary method for increasing the façade's U-value is to add insulation to the system. Rainscreens are an inherently easy way to do this.

How to install rainscreens

A rainscreen is built over a structural exterior wall, which can occur after the wall is built on new construction or added as a retrofit on existing buildings. Rainscreens must be installed around — not on top of — windows. In commercial buildings with lots of windows, smaller panels may be required.

A rainscreen is typically installed over a substrate in three layers — outer, inner, and cavity.

A rainscreen can be attached to multiple substrates, including:

Steel stud walls and sheathing

Concrete

CMU

Wood or mass timber

Brick

The subframe creates the cavity for insulation and allows ventilation and drainage, protecting the structure from rain, snow, humidity, or excess heat.

Panels can be made from many materials, including:

High-pressure laminate

Fiber cement

Aluminum composite

Aluminum plate

Terracotta

Single-skin metal panels

There are a few methods for installing rainscreen cladding:

Face fix — fastener holes are pre-drilled when panels are produced in the factory.

Adhesive secret fix — uses an adhesive to avoid drilling to save time and ensure cost efficiency.

Mechanical secret fix — provides a seamless look, but can only be installed on a certain thickness panels and typically requires extra subframing.

Which NVELOPE system is right for your rainscreen?

NVELOPE is our line of thermally broken rainscreen cladding systems developed for supporting even the most demanding panel materials. SFS offers four primary NVELOPE systems which provide versatility, easy installation, and uncompromising quality.

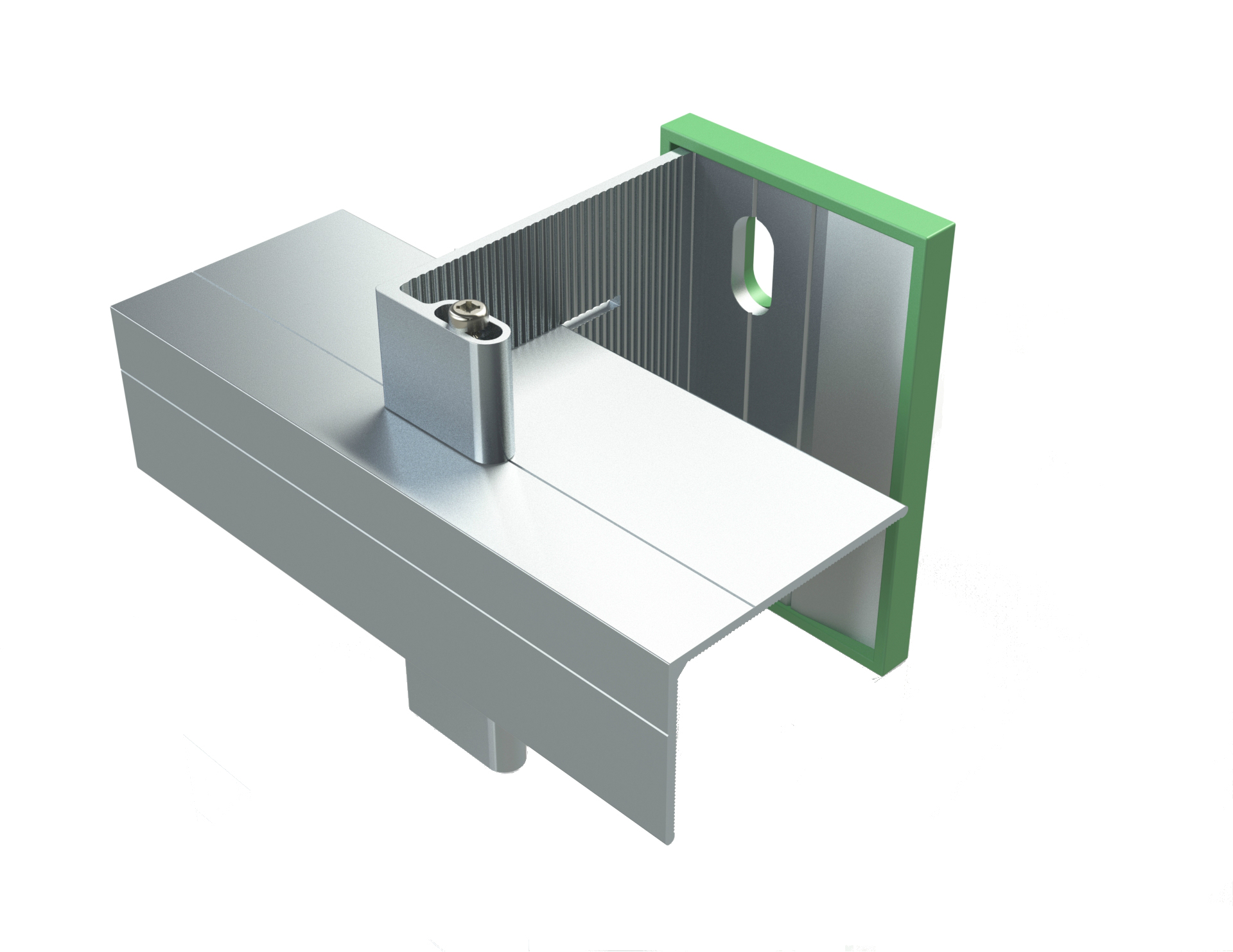

The NV1 NVELOPE system provides an adjustable main support system for horizontally-attached rainscreen cladding applications. NV1 is the back frame for vertical cladding applications and the foundation of our NVELOPE line of rainscreen brackets, rails, and fasteners.

The Museum Of The American Arts & Crafts Movement building leveraged the NV1 system to support the façade with enhanced adjustability without sacrificing the 40,000 square feet of beautiful paneling.

The NVELOPE NH3 system is used to support vertical elements, allowing for varied façade design options. The bracket is secured to the substrate; either steel frame, block work, or timber. The horizontal slot of the bracket can receive an L or lipped L rail, which can be adjusted and secured to allow for expansion and contraction.

The NVELOPE NV3 system is for concealed cladding applications. Horizontal NVELOPE channel profiles are attached to the vertical profiles, and rainscreen panels are hung from and secured with hangers. The NVELOPE flexible point brackets absorb wind loading and allow for expansion and contraction.

Two Trees Management Company leveraged the NV3 system to install a cascade-like façade on Domino Site E in Brooklyn, New York.

TVFCU in Chattanooga, Tennessee also used the NV3 system for their building, except their façade was entirely 3D printed.

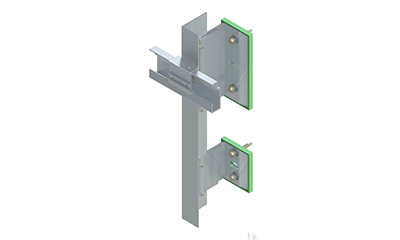

NVELOPE's NVF2F system is a vertical back frame system for floor-to-floor spanning. Brackets are anchored to the building using primary fasteners, and each bracket allows for final alignment and adjustment to suit the external cladding.

The NVF2F ENVELOPE subframe system is ideal for supporting fiber cement, high-pressure laminate (HPL), aluminum composite material (ACM), and metal rainscreen panels.

How do curtain walls and rainscreen systems compare?

Both curtain walls and rainscreens can improve the energy efficiency of the structures they’re attached to. These systems also reduce the impact of the elements by creating a barrier that acts as the primary defense from the weather.

Select the best fasteners for your project

From a fastener perspective, curtain wall and rainscreen systems are very similar. The key differences come from panel material, moisture management, and structural considerations.

Whether you’re considering installing a curtain wall or rainscreen system, it’s imperative to select the proper fasteners. As you explore options, consider the risk of corrosion, load-bearing strength, and pull-out strength.

Environmental factors and material type can impact the risk of corrosion, which can be detrimental to the structure. Avoid the risk of hydrogen-assisted corrosion cracking by strategically utilizing 300-series stainless steel or dual-hardened fasteners.

Order curtain wall fasteners and rainscreen framing and fasteners from SFS

SFS is your partner for superior curtain wall fasteners, rainscreen system framing, and rainscreen fasteners. Our versatile line of fasteners is specifically designed for the unique demands of curtain wall applications, including in corrosive environments. You can explore the full line of curtain wall fasteners, including Flex5 and Bimet300.

For rainscreen systems, the NVELOPE line ensures you’re fully equipped with brackets, rails, and fasteners. With our online planning tools, you can start planning your rainscreen cladding system. Pair with our Center Point System to ensure easy installation for façade panels.

Unsure if you need a curtain wall, rainscreen system, or both? SFS is here to help. Get in touch with our team of experts to design an effective panel system for your next build.

English (Canada)

English (Canada)

čeština (Česká republika)

čeština (Česká republika)

magyar (Magyarország)

magyar (Magyarország)

Deutsch (Deutschland)

Deutsch (Deutschland)

eesti (Eesti)

eesti (Eesti)

español (España)

español (España)

português (Portugal)

português (Portugal)

suomi (Suomi)

suomi (Suomi)

français (France)

français (France)

English (United Kingdom)

English (United Kingdom)

italiano (Italia)

italiano (Italia)

Nederlands (Nederland)

Nederlands (Nederland)

norsk, bokmål (Norge)

norsk, bokmål (Norge)

polski (Polska)

polski (Polska)

svenska (Sverige)

svenska (Sverige)

Türkçe (Türkiye)

Türkçe (Türkiye)